-

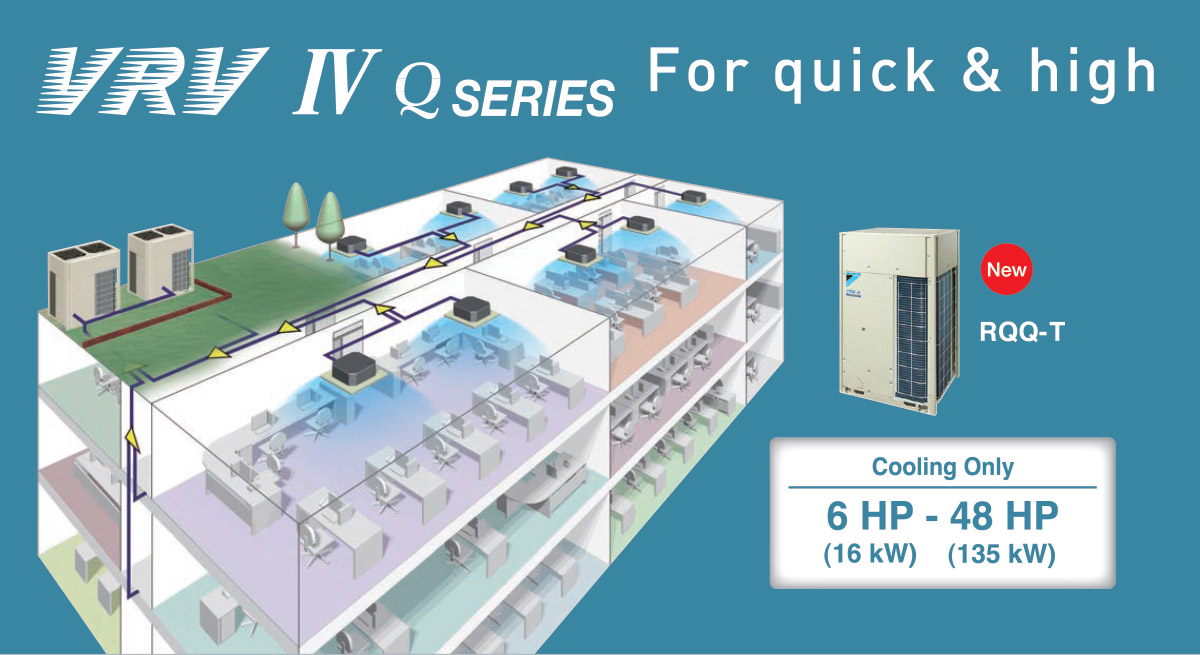

VRV IV Q series

VRV IV Q series

Benefits

Benefits of system replacement

Quick, Quality and Economical

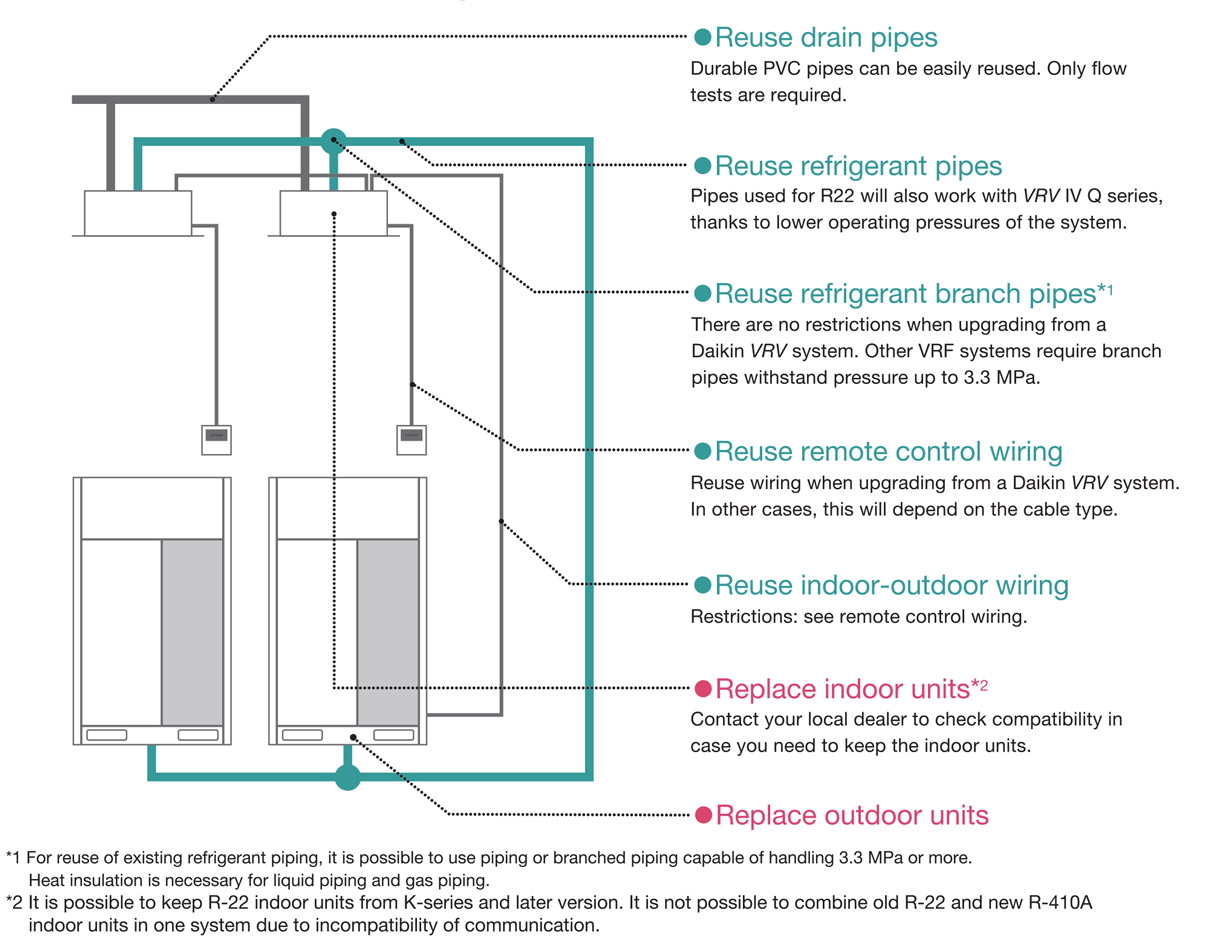

Reuse

Simple use of existing refrigerant piping.

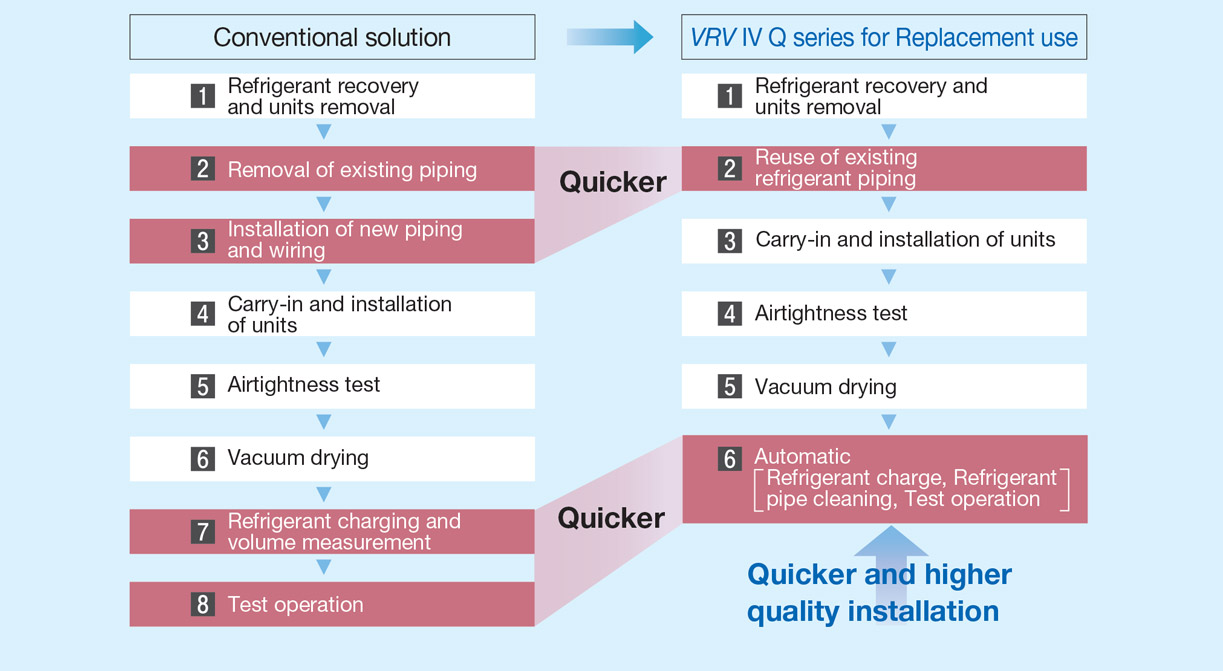

In the past, special equipment and work was needed to clean pipes when using existing piping, but this is no longer required. A new function automatically deals with contamination inside piping during refrigerant charging, eliminating the work involved in cleaning.

Even applicable for non-DAIKIN systems!

The Daikin low-cost upgrade solution

Automatic

Refrigerant charging, cleaning and test operation done with just a single switch.

The unique automatic refrigerant charge eliminates the need to calculate refrigerant volume, simplifying the installation process. Not knowing the exact piping lengths because of changes or mistakes in case you didn't do the original installation or replacing a competitor installation no longer poses a problem. Furthermore, there is no need to clean inside piping as this is handled automatically by the VRV IV Q unit.

Time saving

Enables smooth replacement of air conditioning with less effect on operations and users in the building.

Cost saving

Work costs for pipe removal, installation and insulation account for much of the total cost. By the reuse of existing piping, 35% of cost down can be realized compared to installing new pipes.

ReLated services

Design flexibility

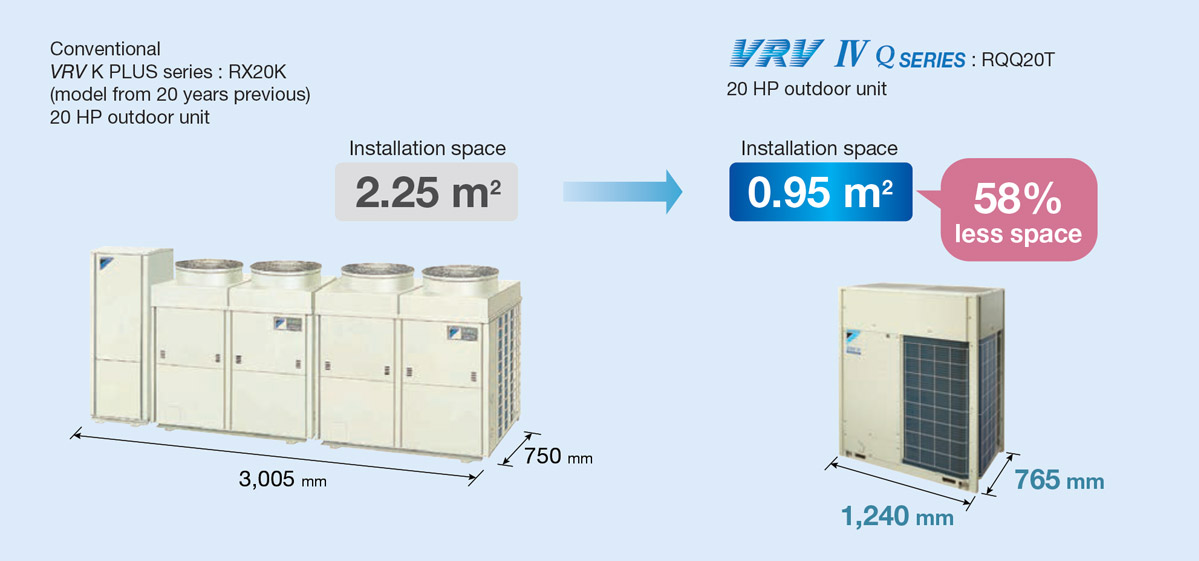

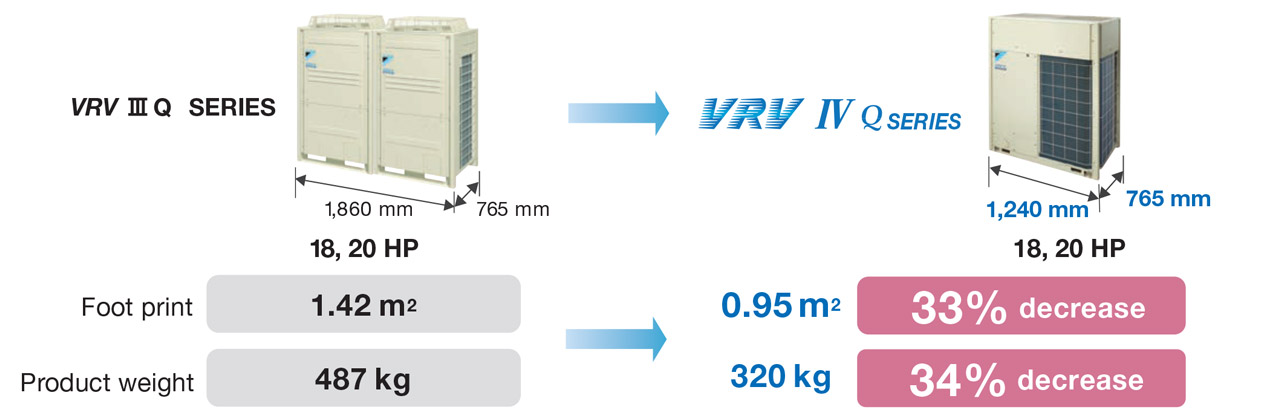

Significantly more compact outdoor unit enables the effective use of limited space!

Compact design enables the effective use of space taken up by existing machinery

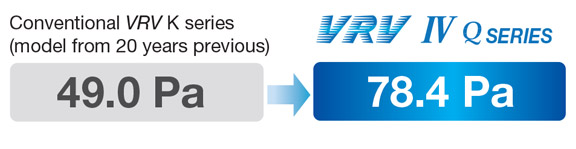

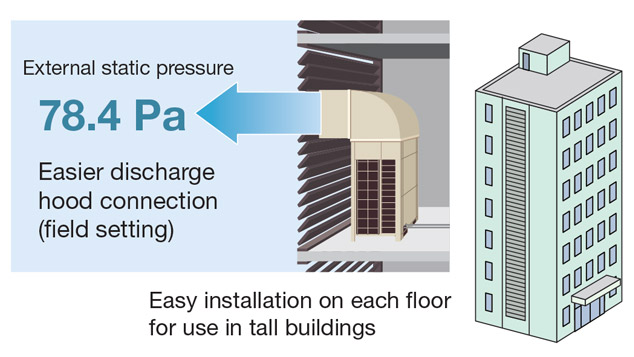

High external static pressure 78.4 Pa

Small and light, significantly reducing constraints during carry-in

Can be carried on a cart

Can be carried on a cart

System flexibility

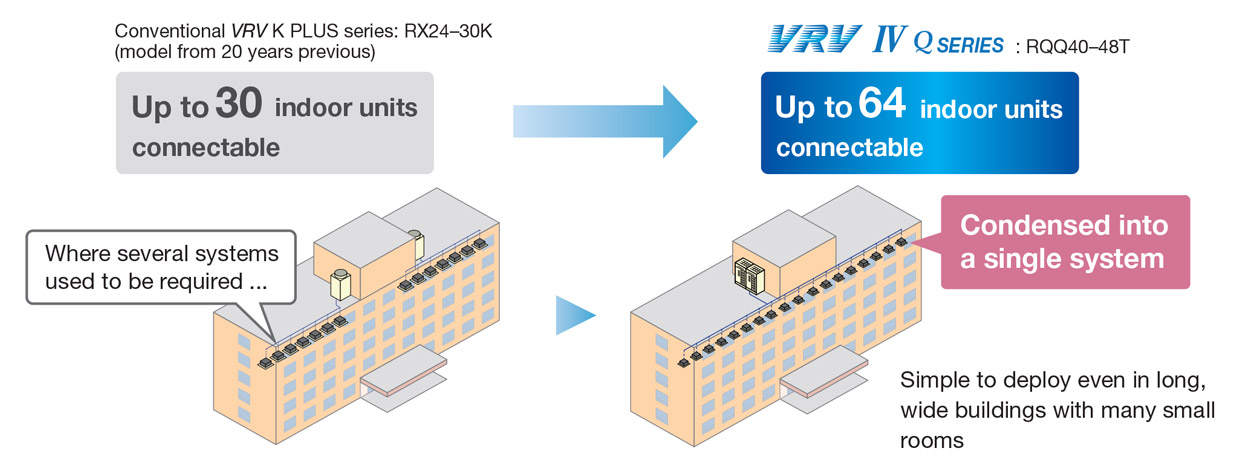

An increased number of connectable indoor units in a single system

More indoor units can be connected in a single system, enabling consolidation of existing piping!

The number of connectable indoor units has been drastically increased from 30 to 64.

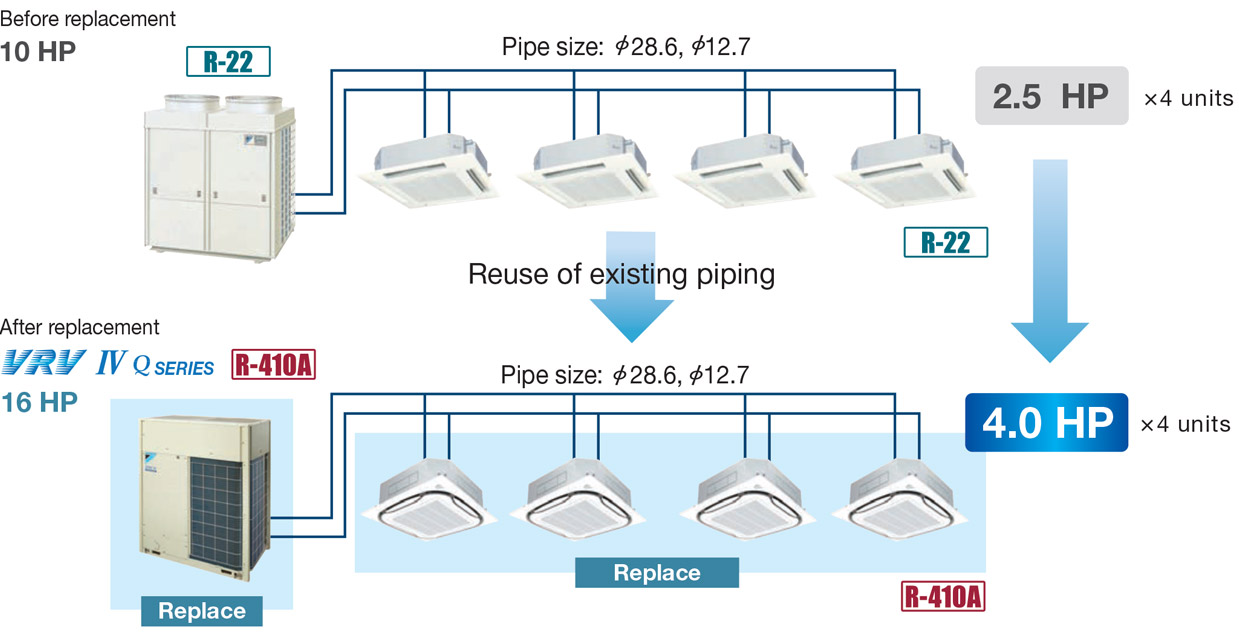

Enables increased capacity

System can be upgraded using existing piping

VRV IV Q series for replacement use enables the system capacity to be increased without changing the refrigerant piping. For example, it is possible to install a 16 HP VRV IV Q series using the refrigerant piping of an 10 HP R-22 system.

For reuse of existing refrigerant piping, it is possible to use piping or branched piping capable of handling 3.3 MPa or more.

Heat insulation is necessary for liquid piping and gas piping.

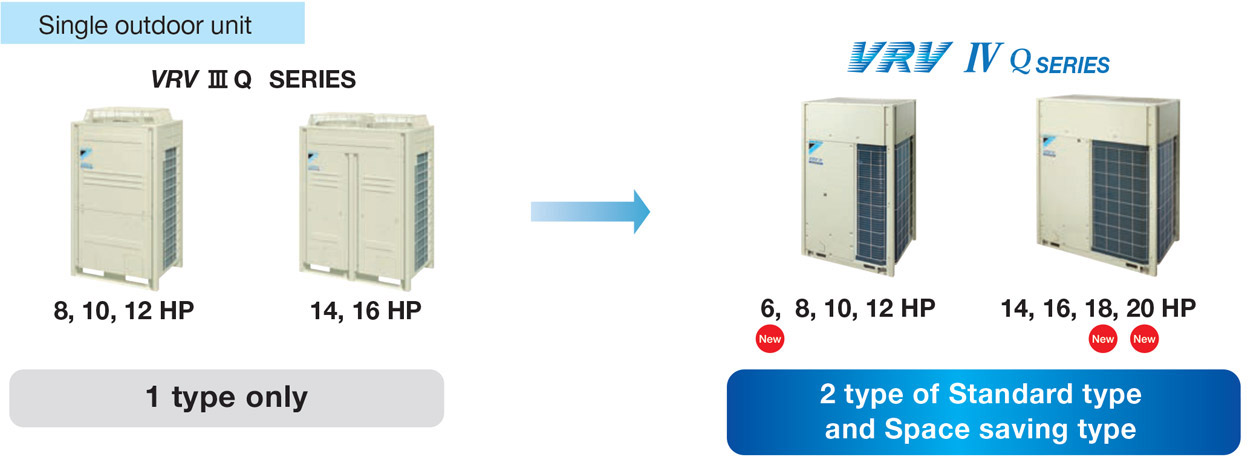

Enhanced Lineup

2 types up to 48 HP

With its enhanced lineup of 2 types and Standard and Space saving types, VRV IV Q series outdoor units offer a high capacity up to 48 HP to meet an ever wider variety of needs.

Compact & Light Weight Design

New Space Saving type with refined design

As a leading global innovator, Daikin advanced from the conventional 2 module combination to a single module for 18 and 20 HP models. This allows the installation area to reduce by 33% as compared to the previous models.

Energy Saving

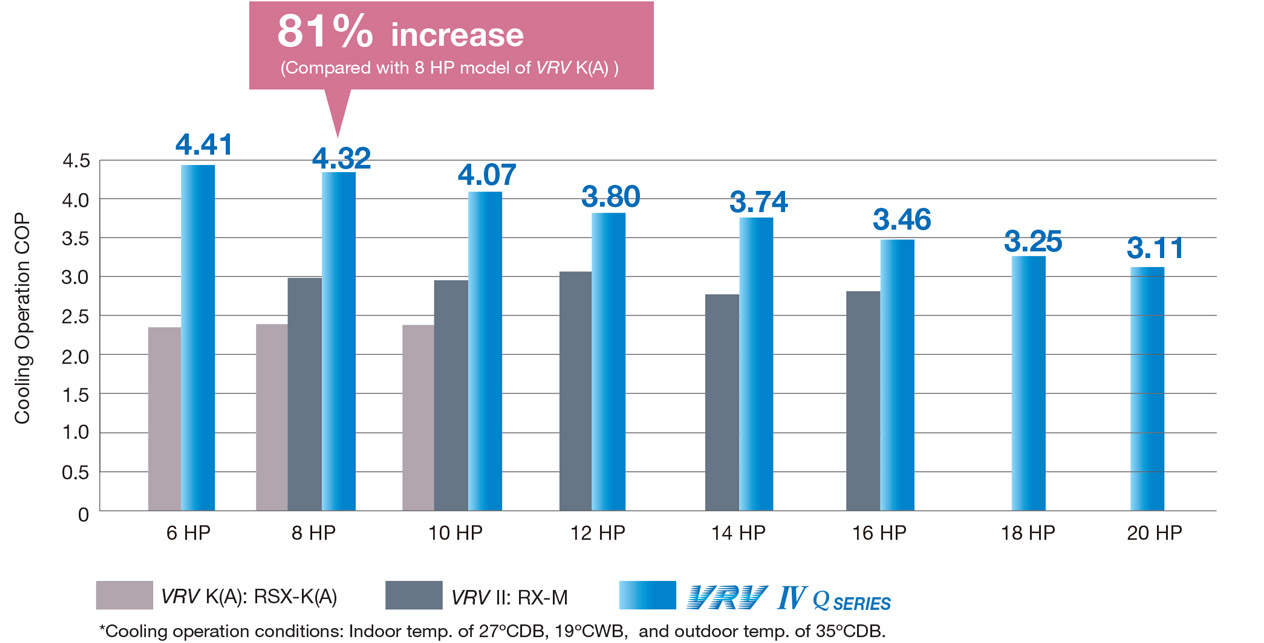

Higher Coefficient of Performance (COP)

COP at 100% operation load

VRV IV Q series delivers highly efficient performance, contributing to high energy savings.

COP for 10 HP

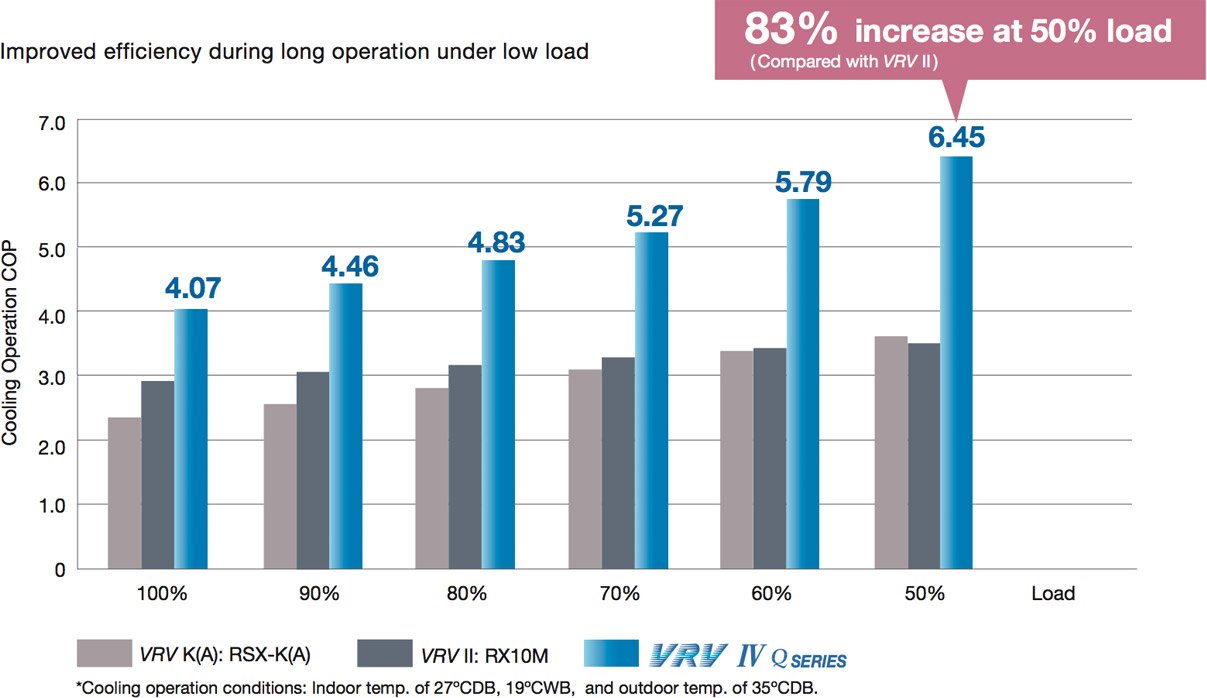

Improved efficiency during long operation under low load

Features

VRT-Variable Refrigerant Temperature

State-of-the-art energy saving technology for VRV system

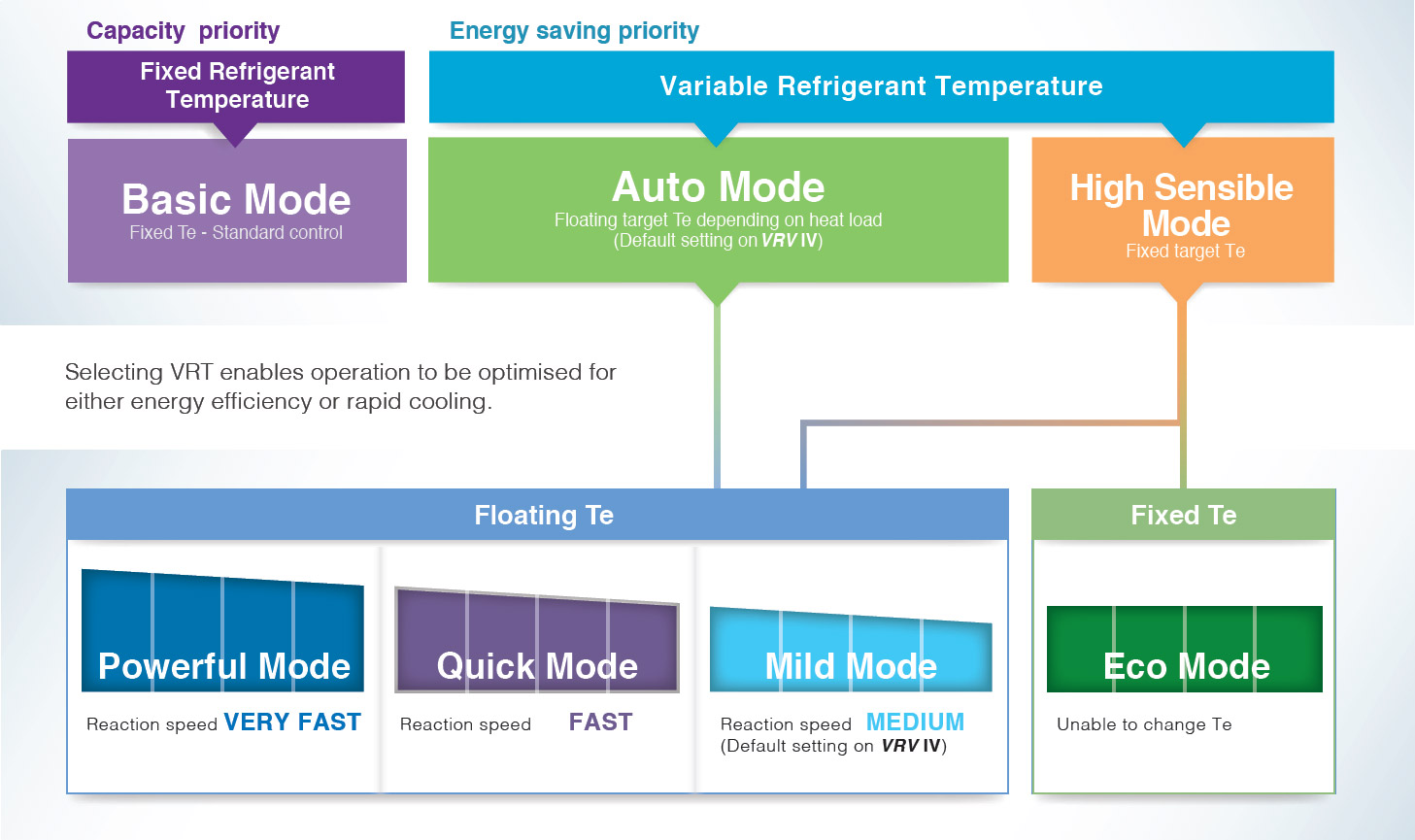

Customise your VRV system for optimal annual efficiency

The new VRV IV Q series now features VRT technology. VRT automatically adjusts refrigerant temperature to individual building and climate requirement, thus further improving annual energy efficiency and maintaining comfort. With this excellent technology, running costs are reduced.

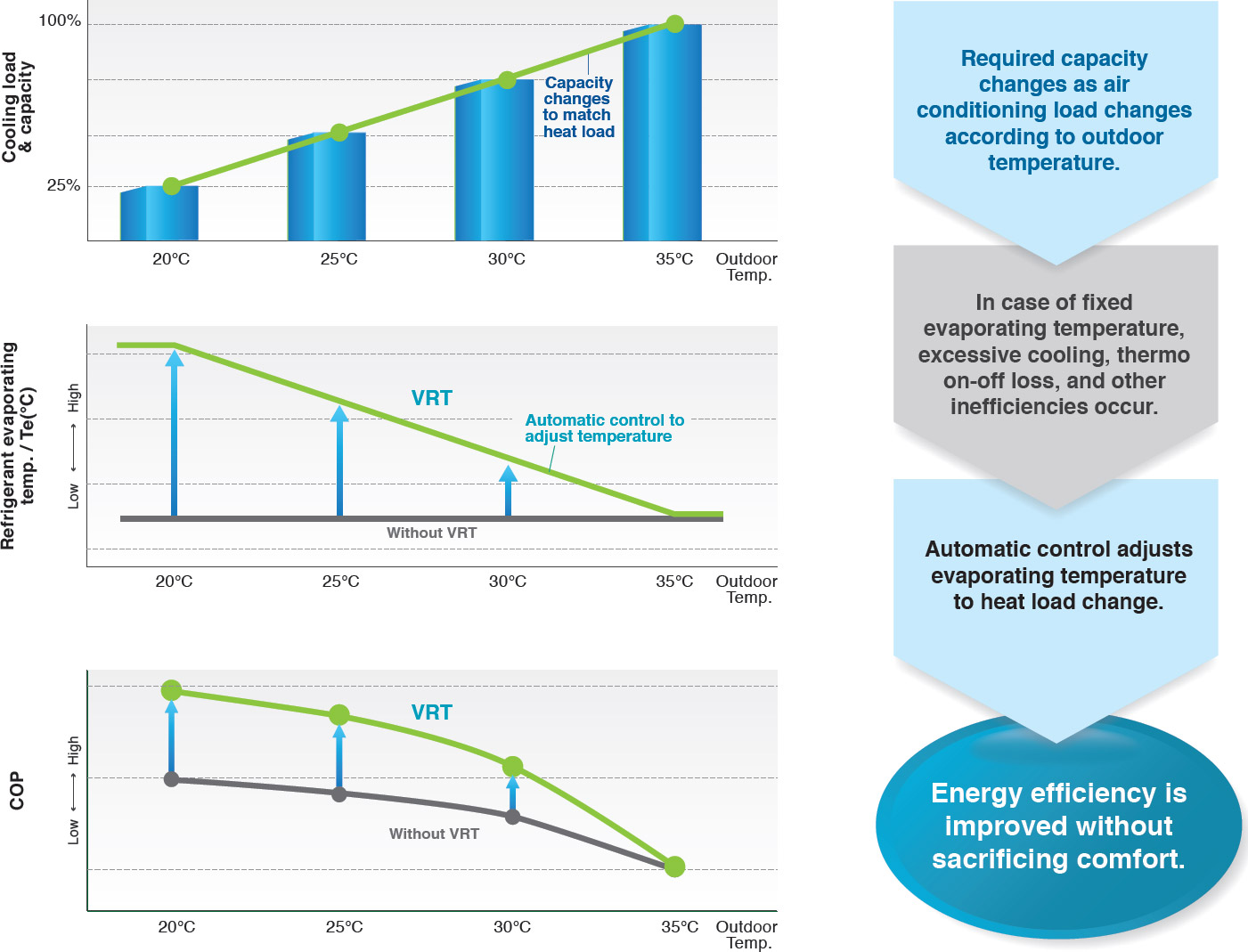

How is energy reduced?

During cooling, the refrigerant evaporating temperature (Te) is raised to minimise the difference with the condensing temperature. Compressors work less, and this reduces power consumption.

Typical changes in evaporating temperature and COP depending on changing indoor load

New system, saving more energy

Basic mode is selected to maintain optimal comfort.

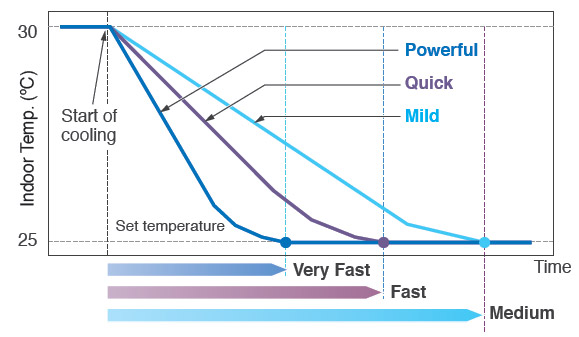

VRT is selected to save energy and prevent excessive cooling.

VRT offers quicker cool down to shorten uncomfortable pull down time.

| Powerful Mode |

|

|---|---|

| Quick Mode |

|

| Mild Mode |

|

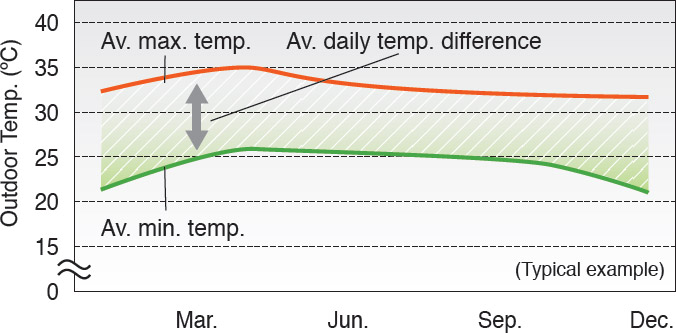

Recommended for use in these situations

- Cooling only regions having differences in daily temperature.

- VRT is particularly effective at night when temperatures are low.

Advanced Technologies Achieve

New technology that enables use of existing piping

New tested contamination collection meth

A new method collects contamination from existing piping, eliminating compressors and electric valves malfunction.

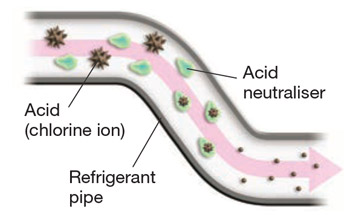

Acid

An acid neutraliser agent is added to disable acids (chlorine ions), which cause corrosion.

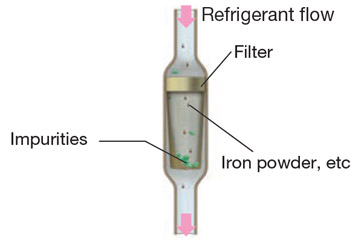

Impurities

A generously sized filter is provided inside the refrigerant circuit which traps impurities.

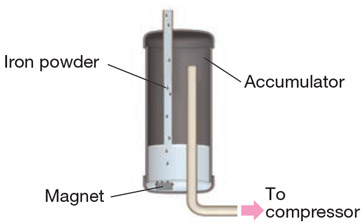

Iron powder

A magnet is installed inside the accumulator where liquid refrigerant accumulates. The magnet attracts iron powder to keep the system clean.

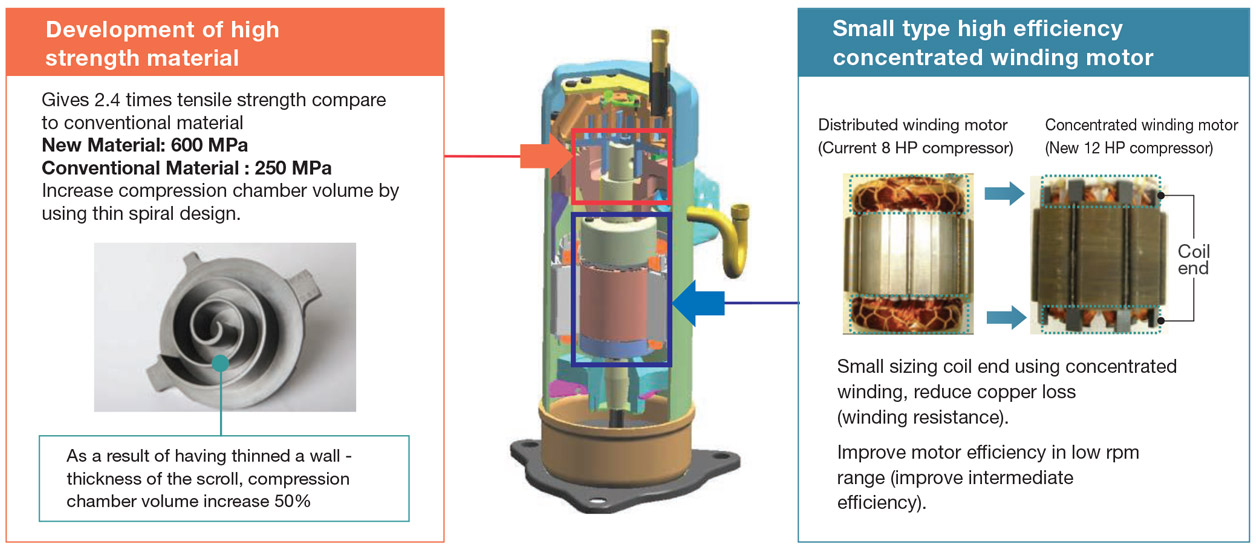

Large capacity all DC inverter compressor in compact casing

Large capacity all DC inverter compressor using high tension strength material, realise 12 HP compressor using 8 HP casing.

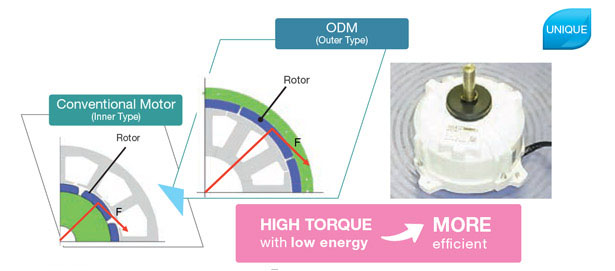

Outer Rotor DC Motor (ODM)

Only Daikin adapted ODM with feature of stable rotation and volumetric efficiency

Advantages of ODM

Thanks to large diameter of the rotor,

- Large torque with same electromagnetic force

- Stable rotation in all range, and can be operated with small number of rotations

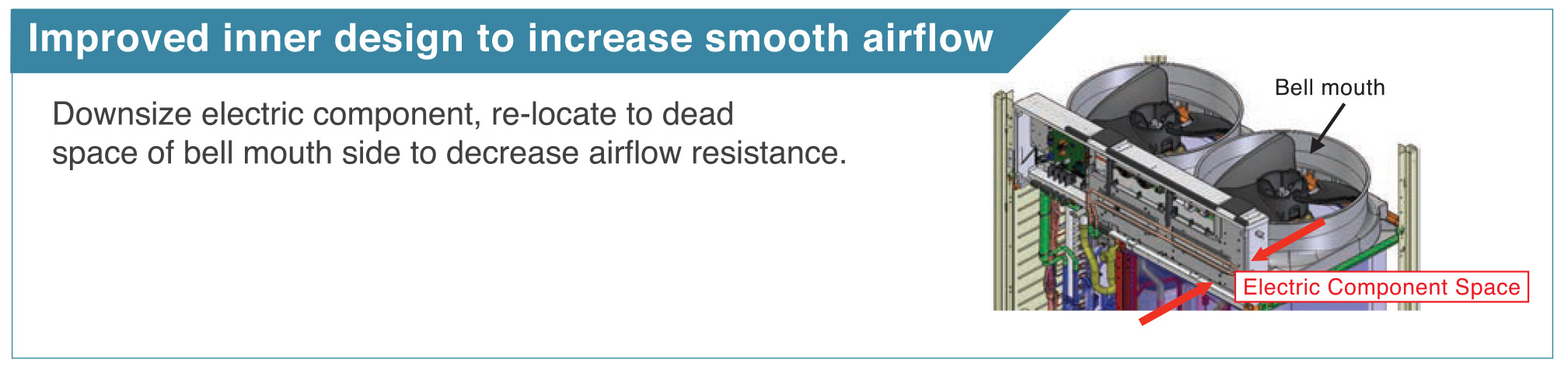

Highly integrated heat exchanger

Improve performance by increasing heat exchanger area while maintaining the same installation space.

Excellent Performance

Various advanced control main PC board

SMT* mackaging technology

- SMT packaging technology adopted by the whole computer control panel improves the anti-clutter performance.

- Protects your compter boards from the adverse effect of sandy and humid weather.

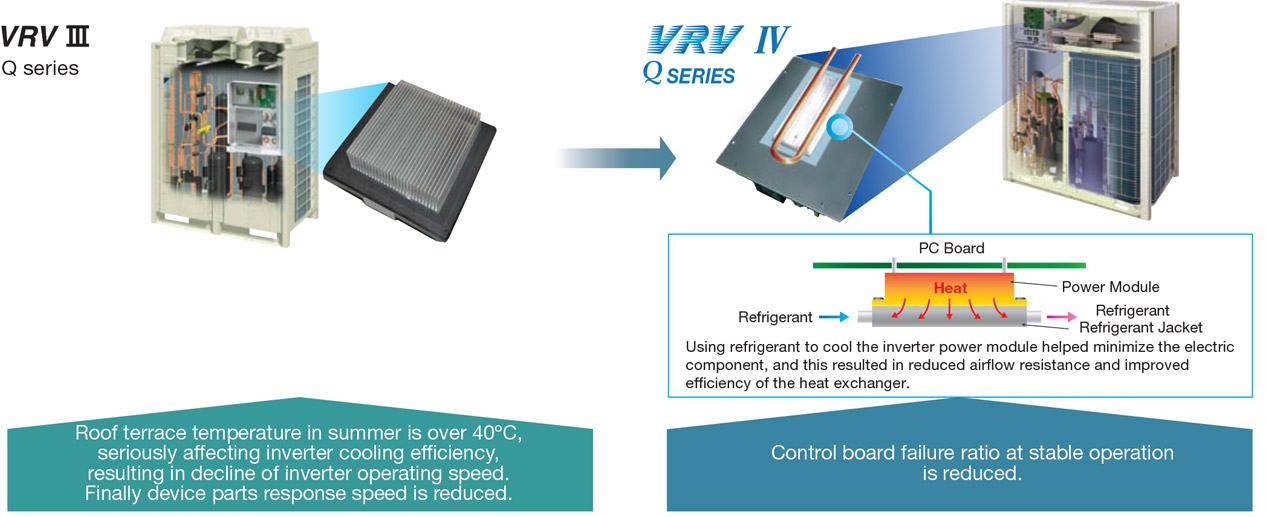

Refrigerant cooling technology, ensures stability of PCB temperature

Improve reliability at high ambient temperature

It is possible to cool the inverter power module stability even at high ambient temperature.

This helps to keep air-conditioning capacity and also reduces failure rate.

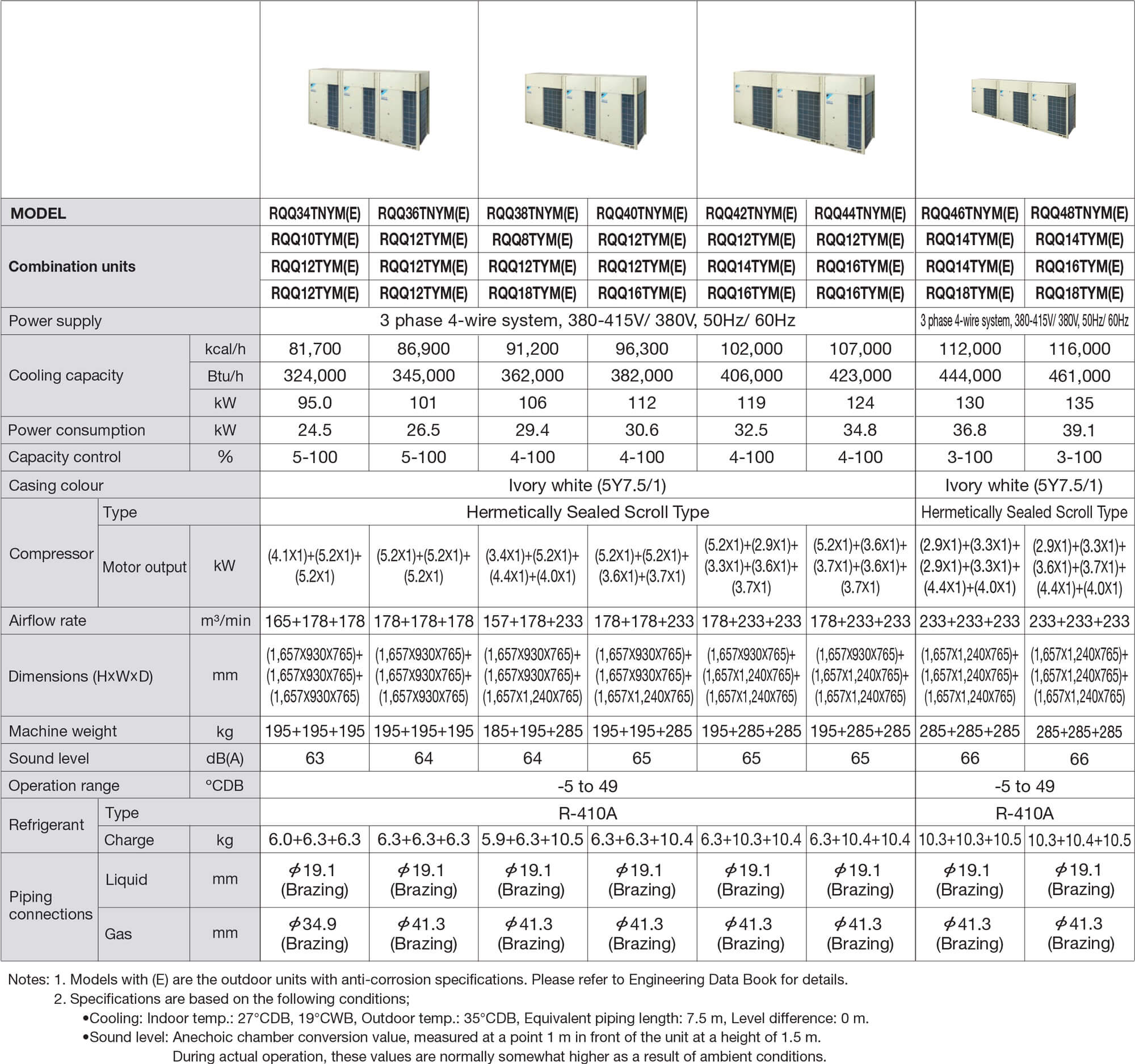

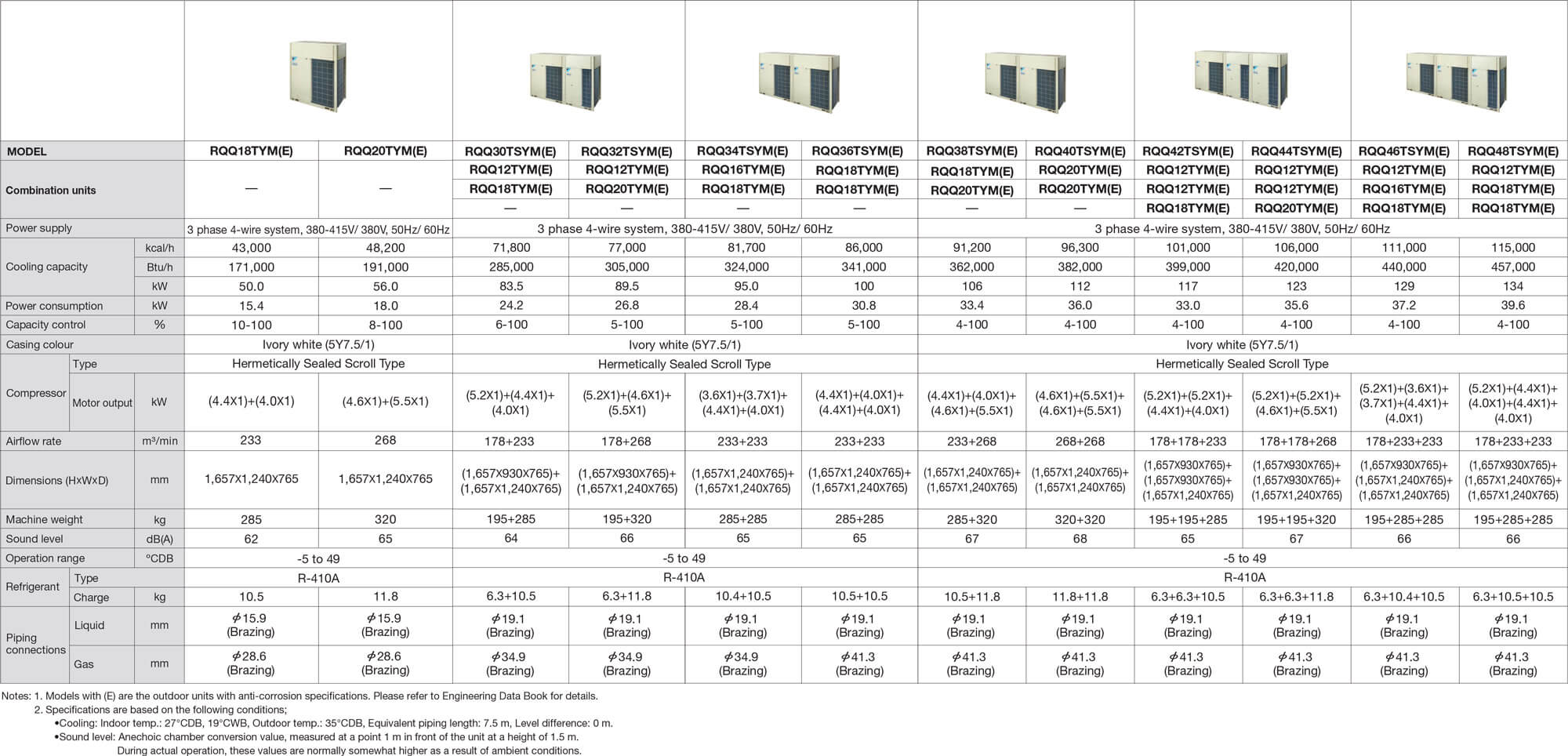

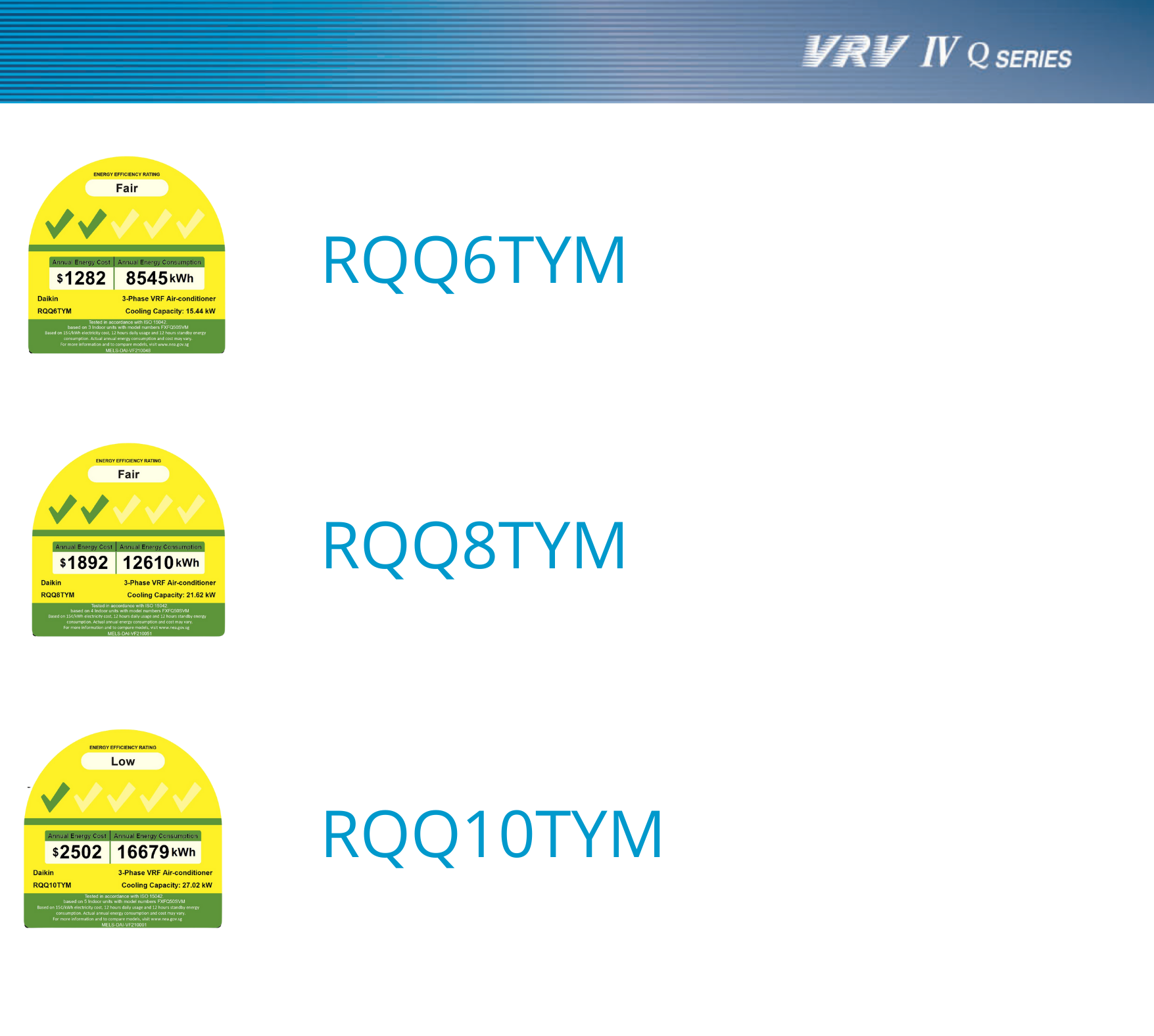

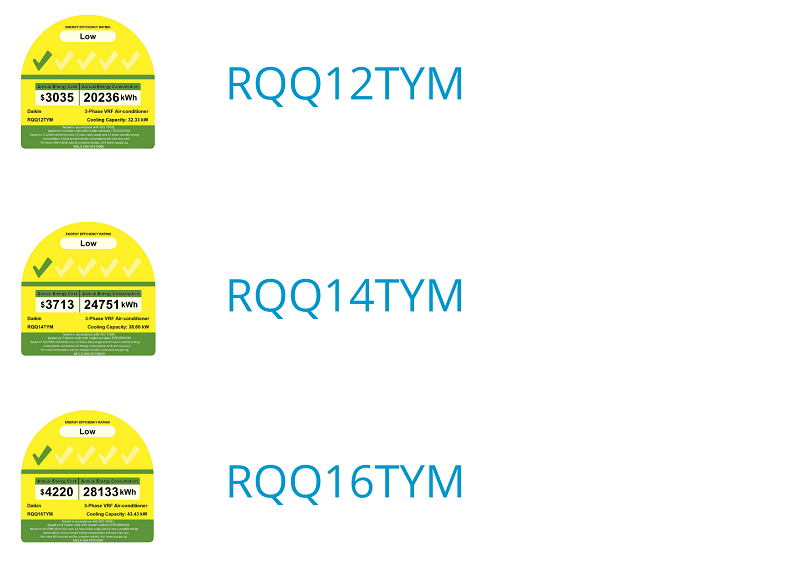

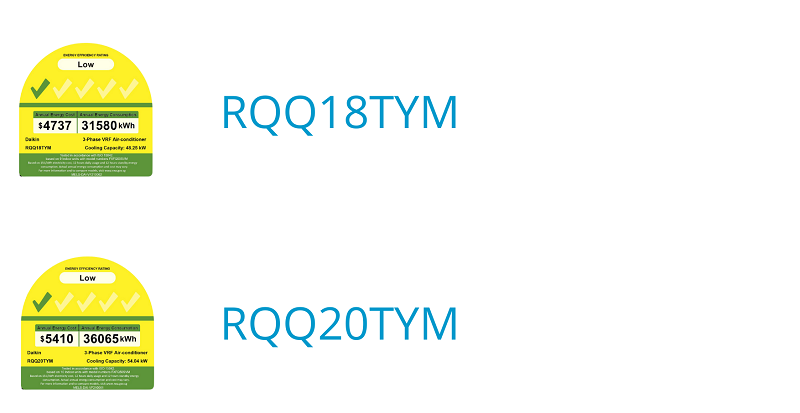

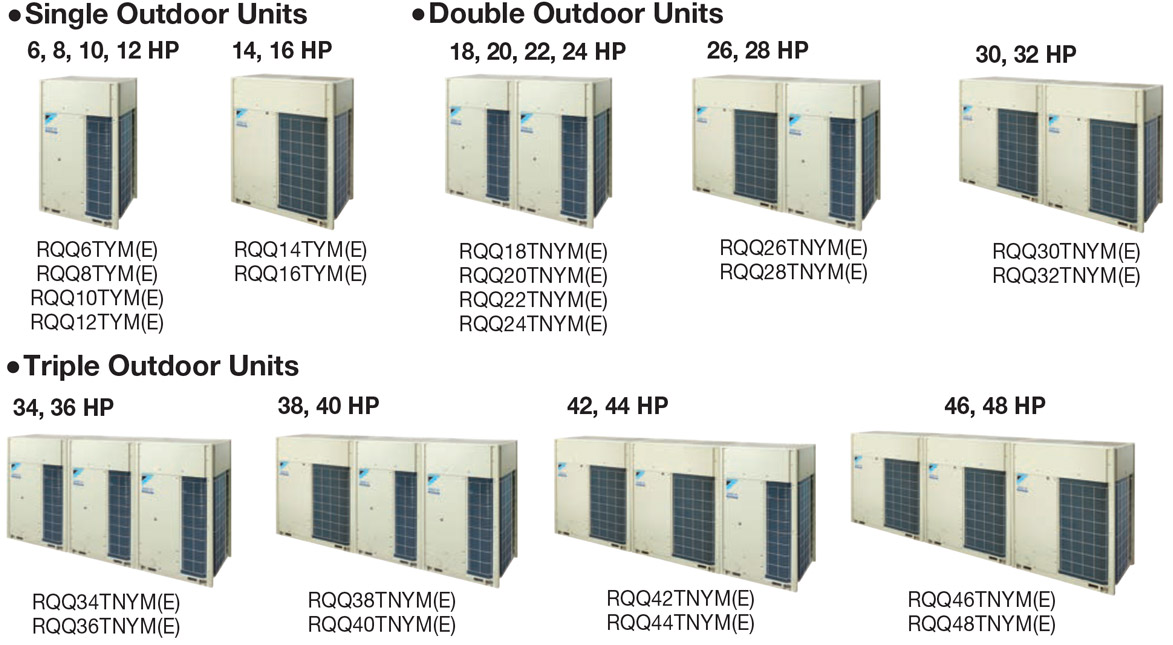

Range

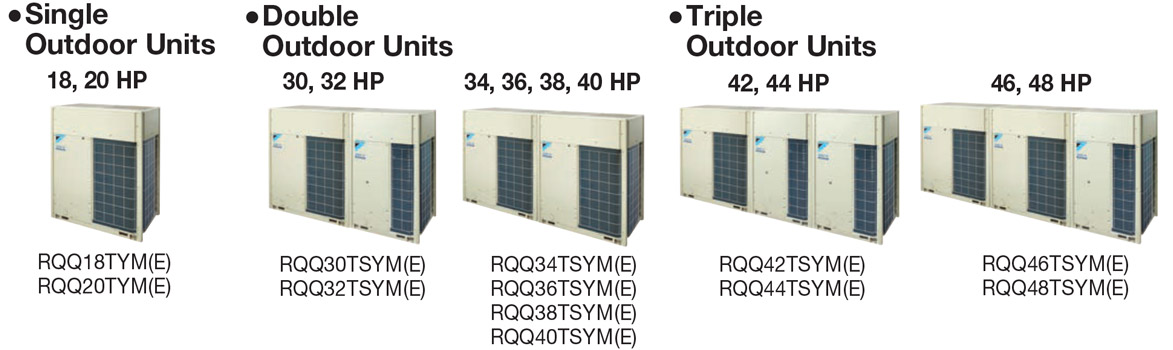

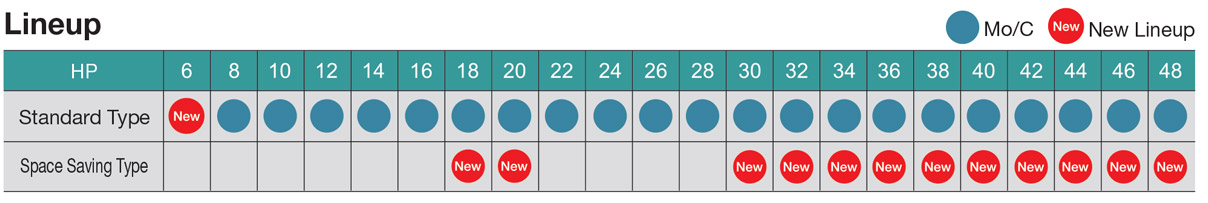

Outdoor Unit Lineup

Enhanced lineup to 2 types

- With its enhanced lineup of 2 types and Standard and Space Saving types, VRV IV Q series outdoor units offer a high capacity up to 48 HP to meet an ever wider variety of needs.

- The single outdoor unit has only 2 different shapes and dimensions, not only simplifying the design process, but also bringing the system flexibility to a new level.

- With the outdoor unit capacity increased in increment of 2 HP, customers' needs can be precisely met.

- Outdoor units with anti-corrosion specifications (-E type on request) are designed specifically for use in areas which are subject to salt damage and atmospheric pollution.

Standard Type

Space Saving Type

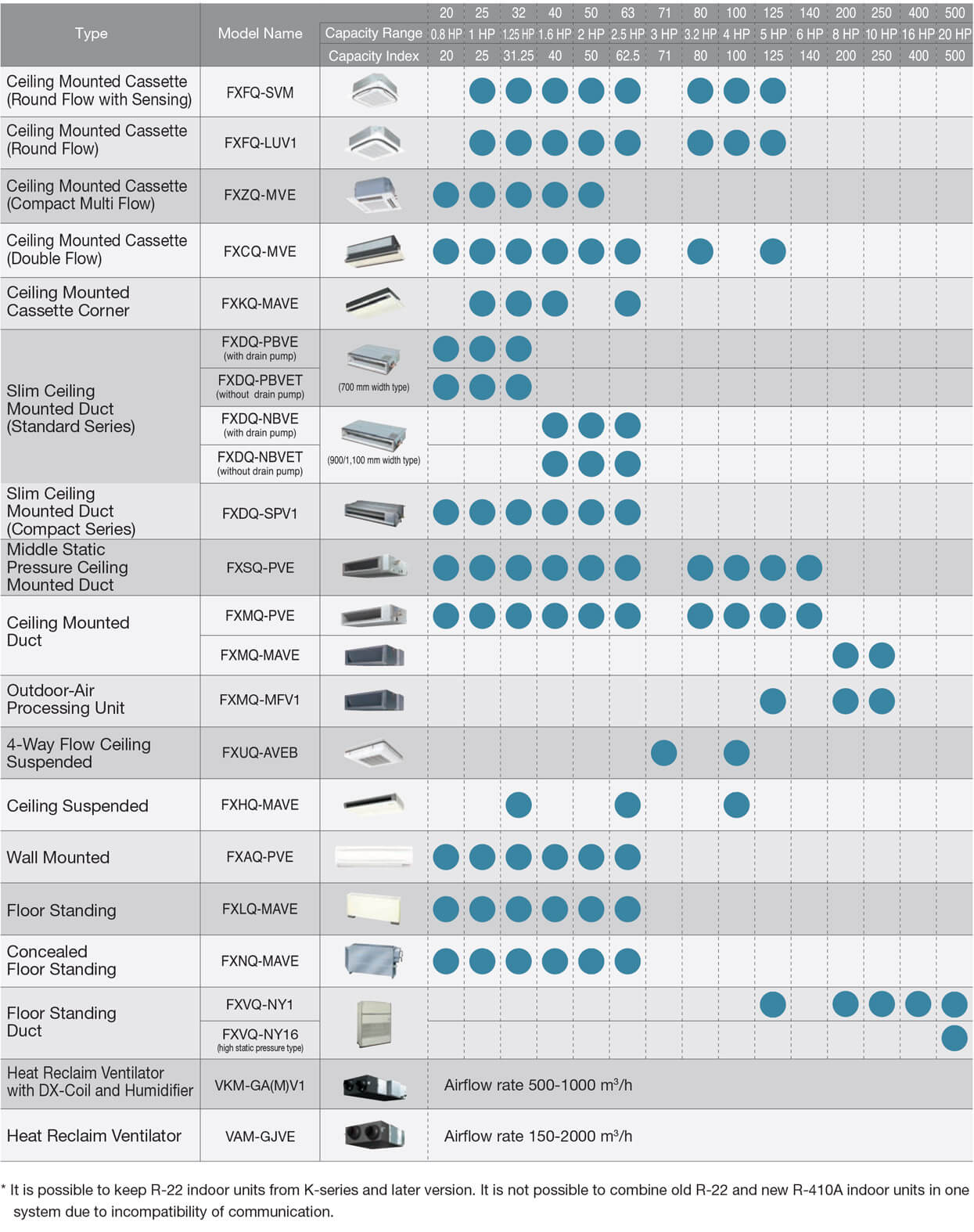

Indoor Unit Lineup

Variety of indoor unit

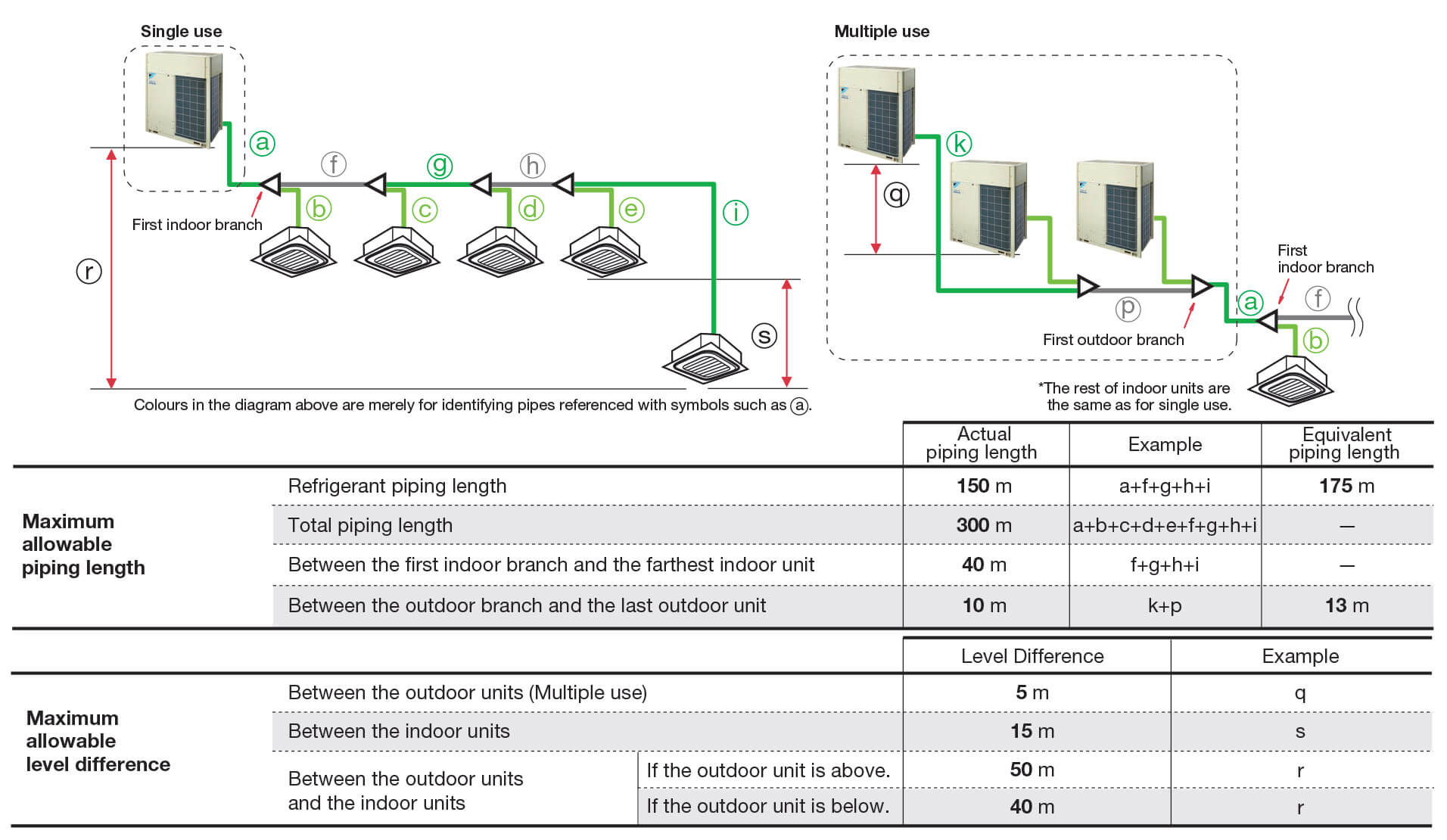

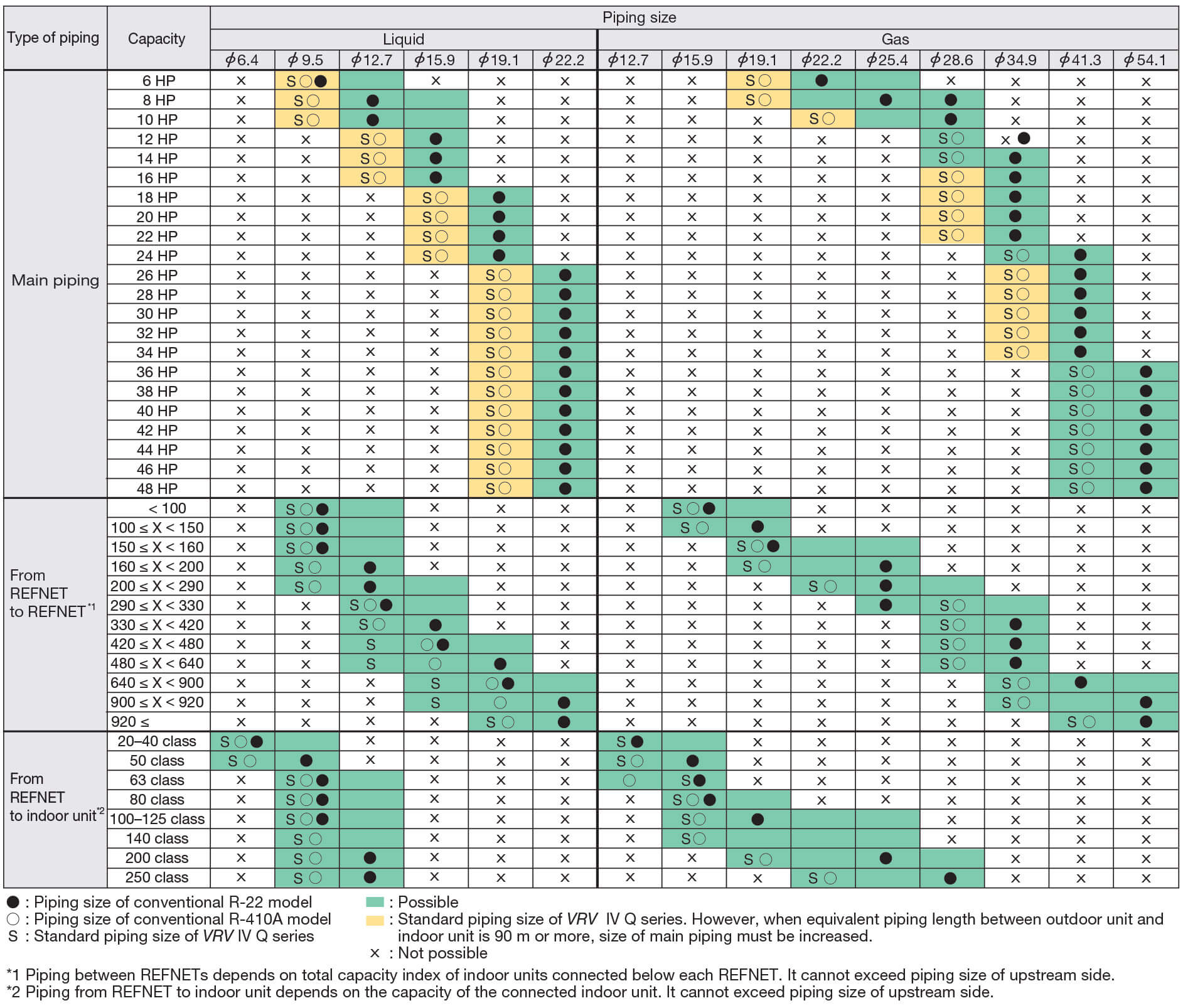

Guidelines for reuse of existing refrigerant piping

Piping limits for reuse of existing piping

Reusability of existing piping for VRV IV Q series

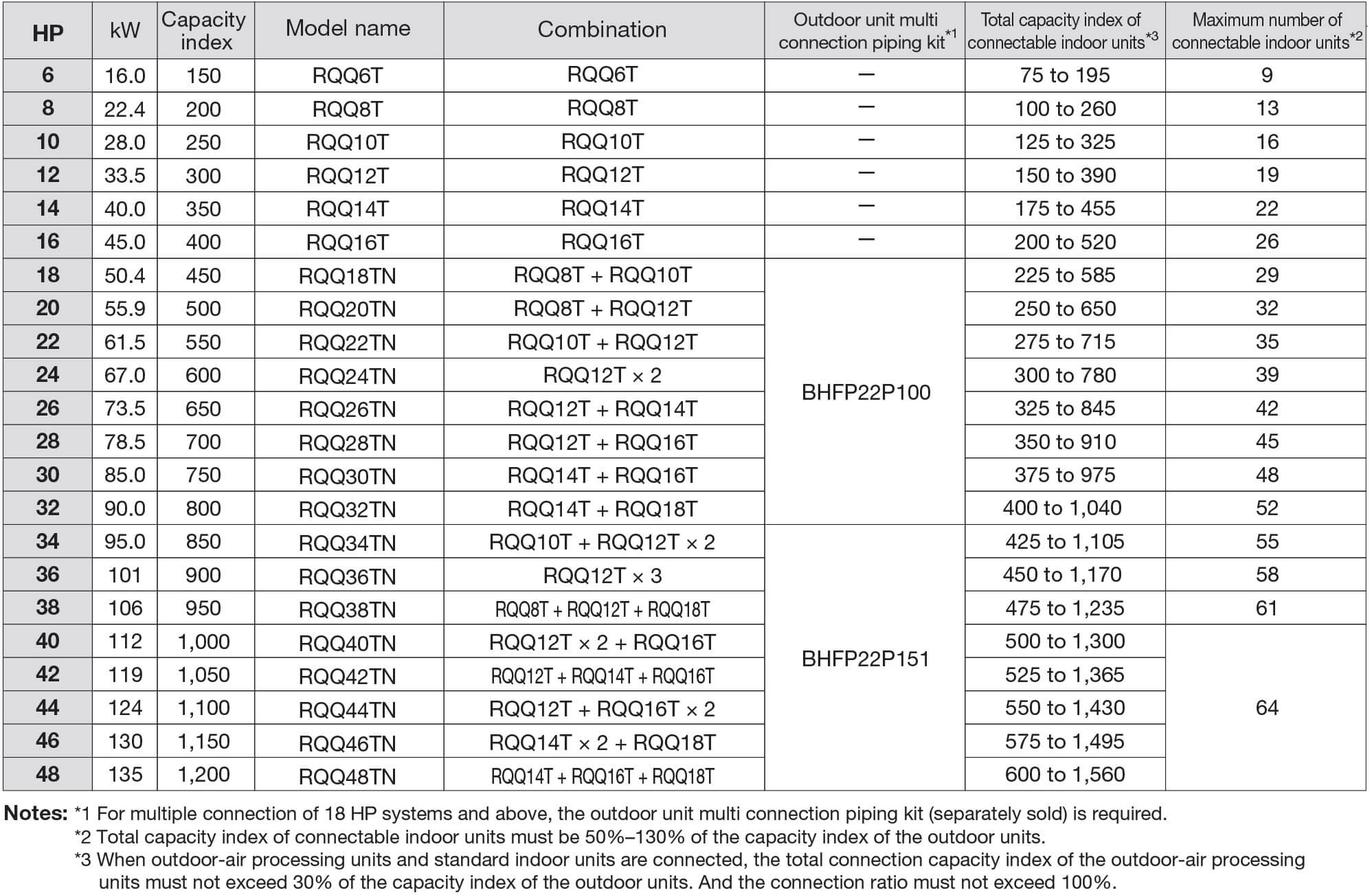

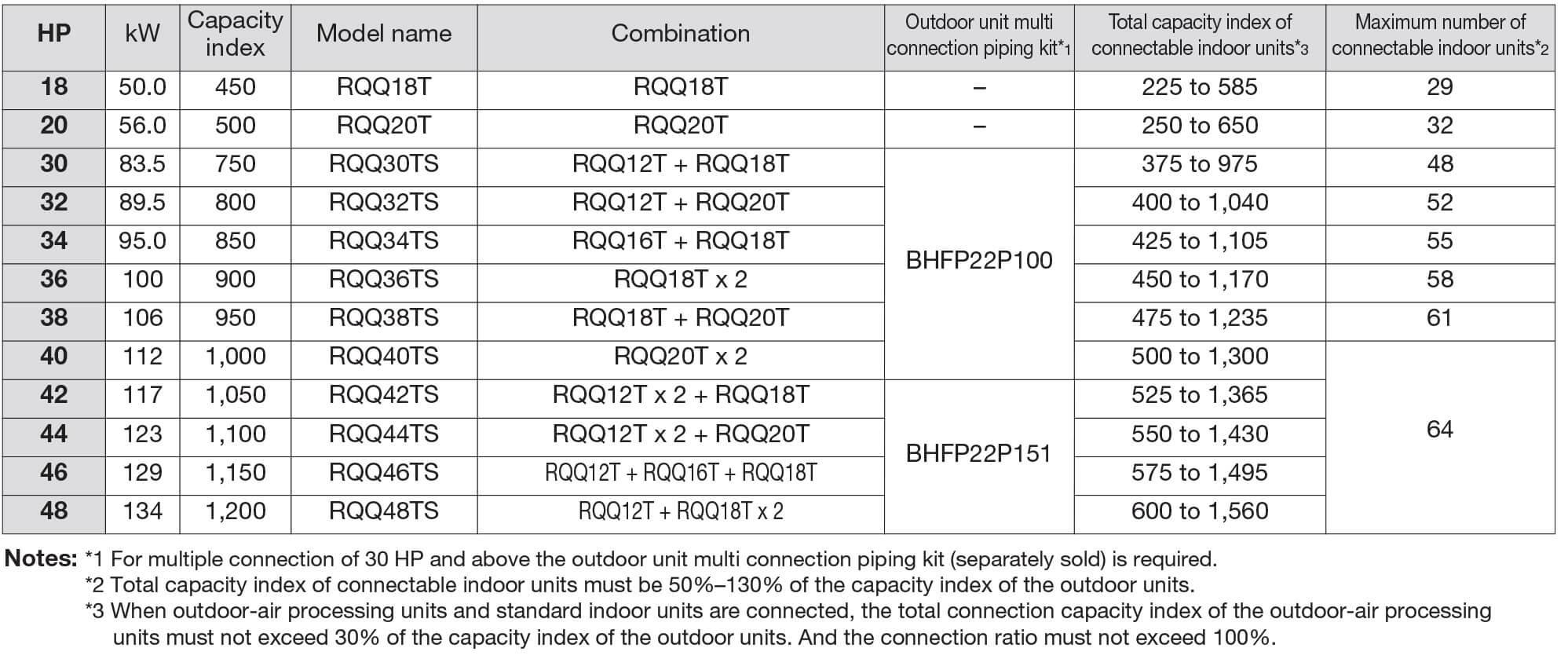

Outdoor Unit Combinations

Standard Type

Space Saving Type

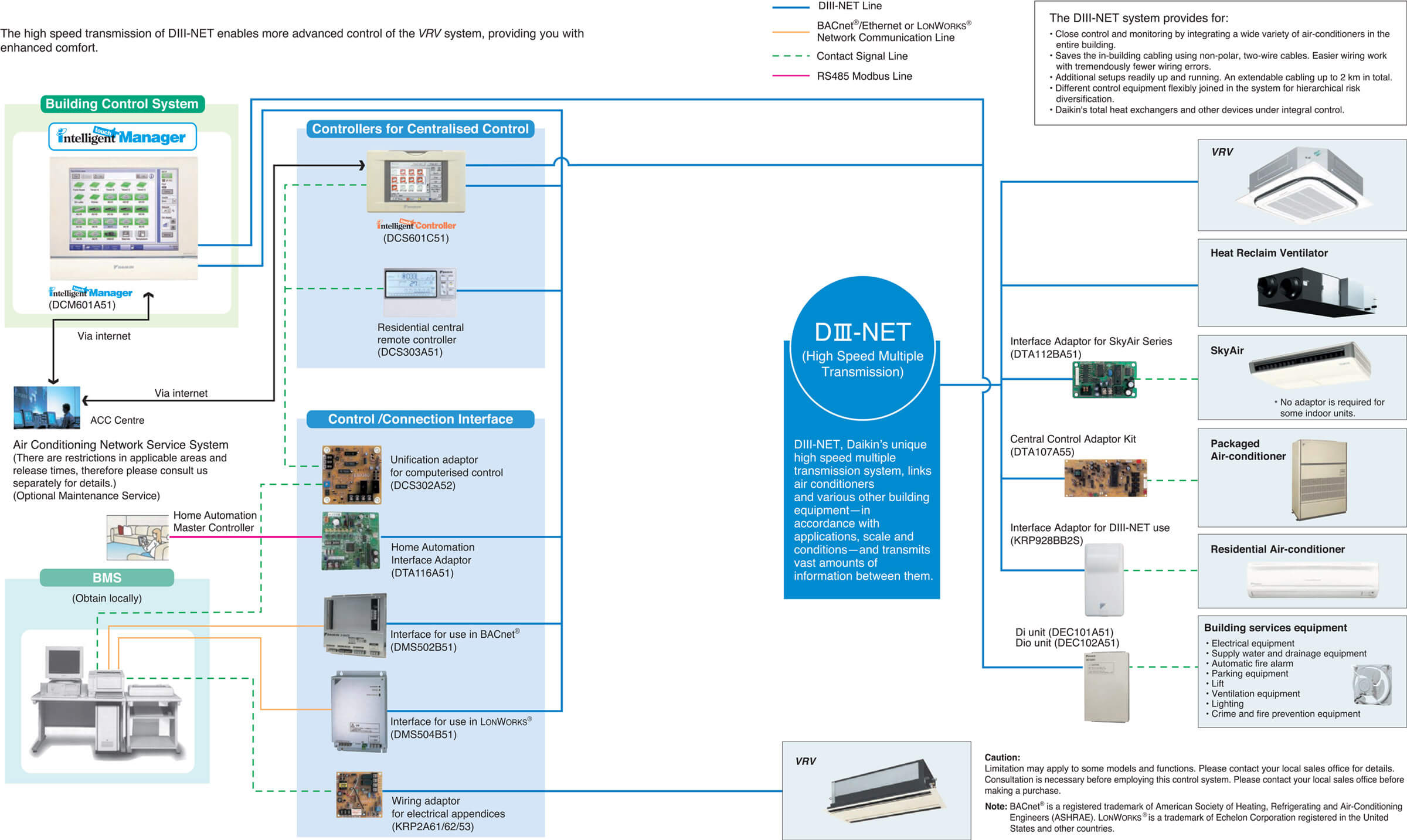

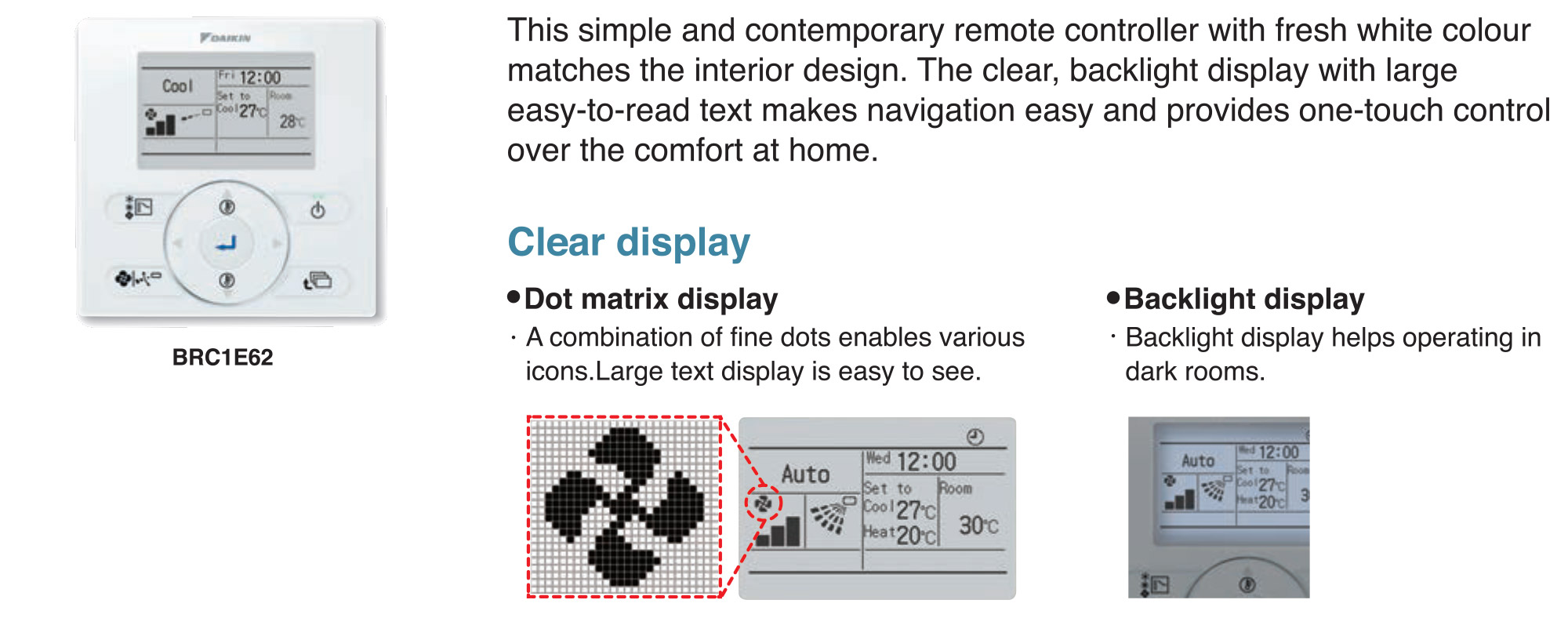

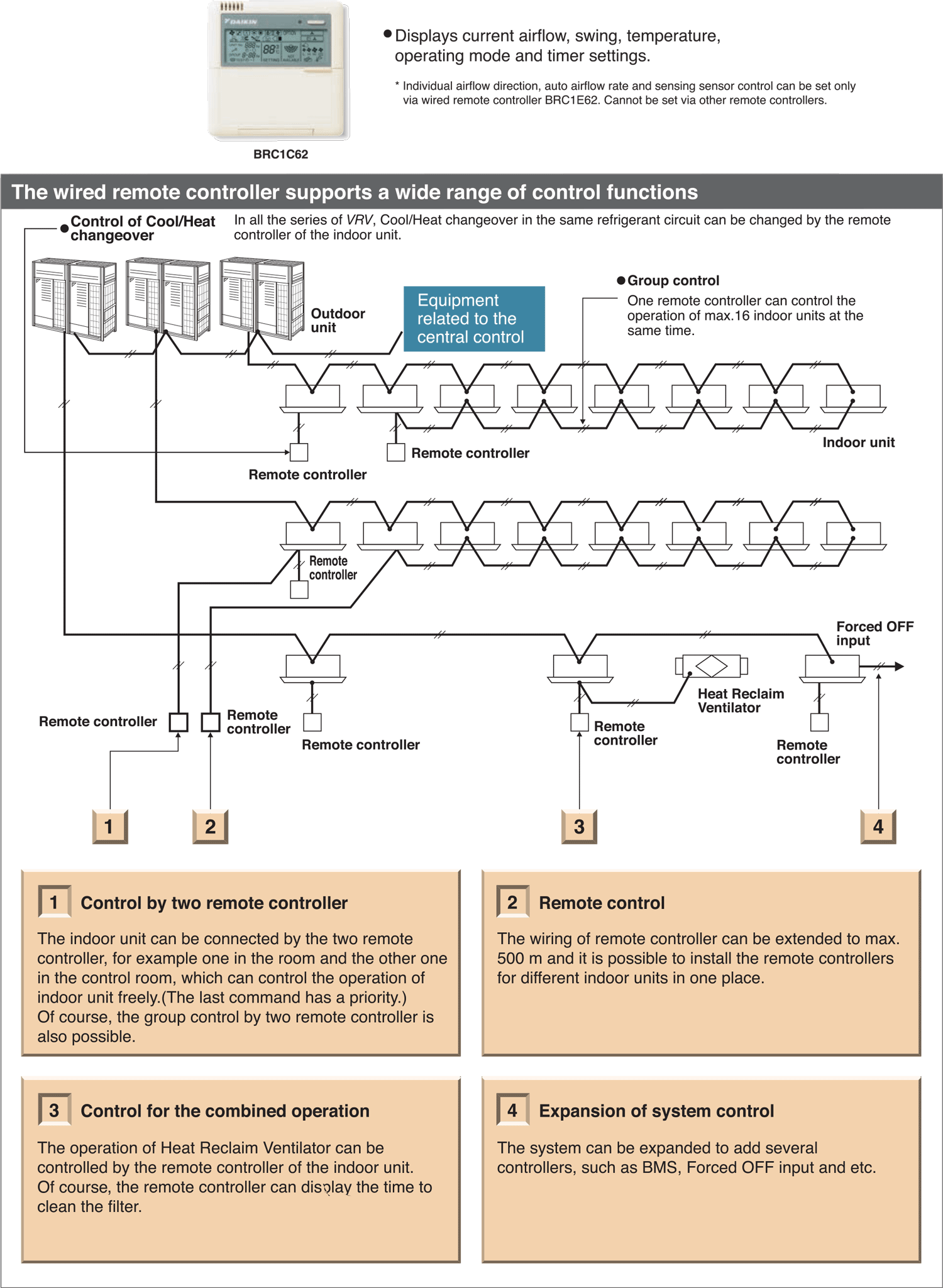

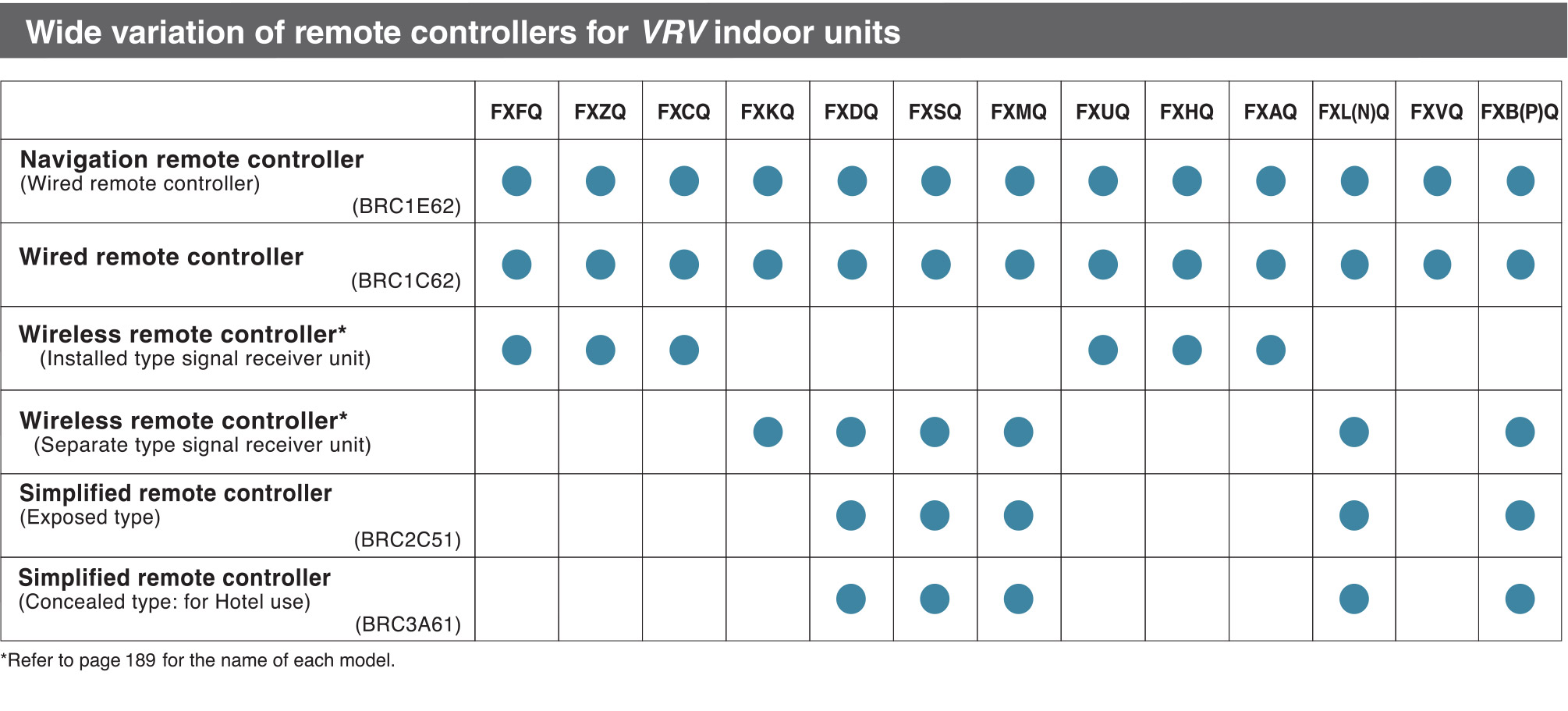

Controller

Individual Control Systems for VRV Indoor Units

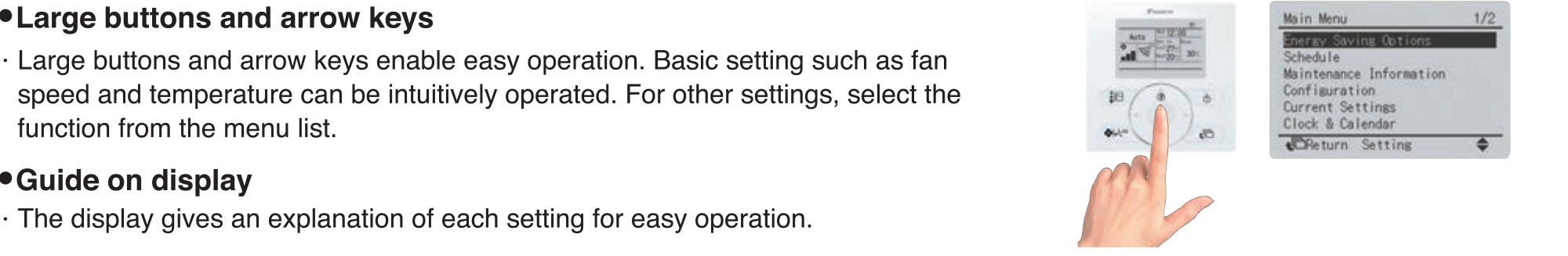

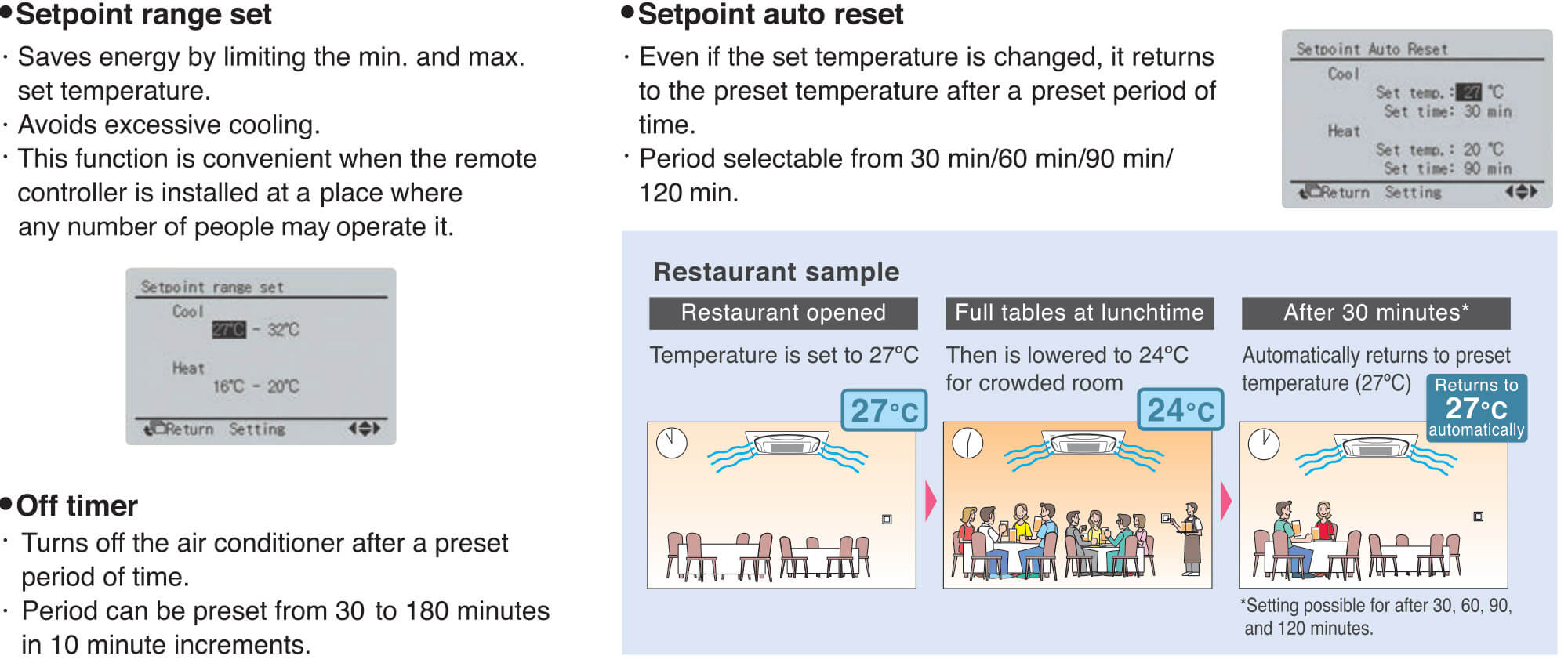

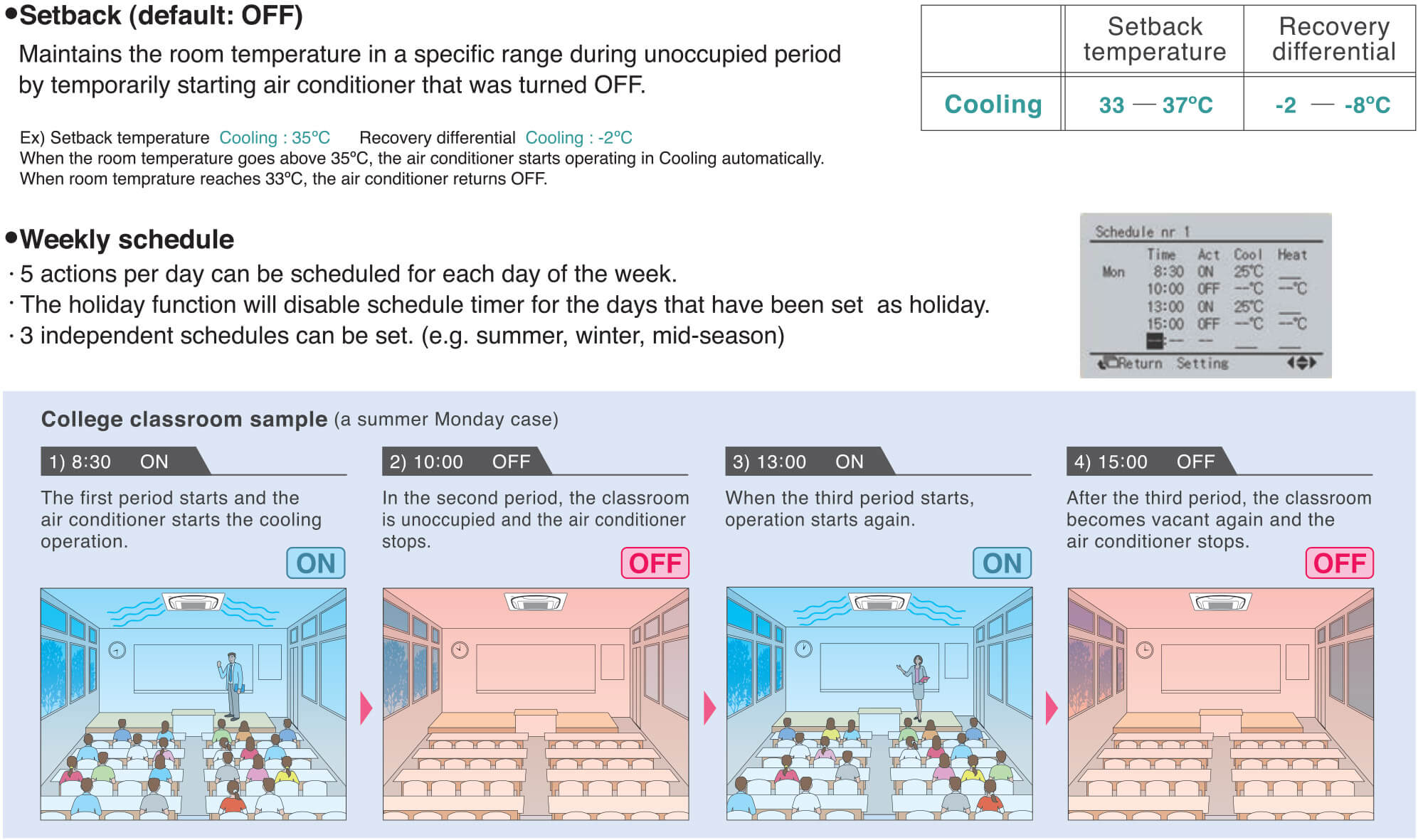

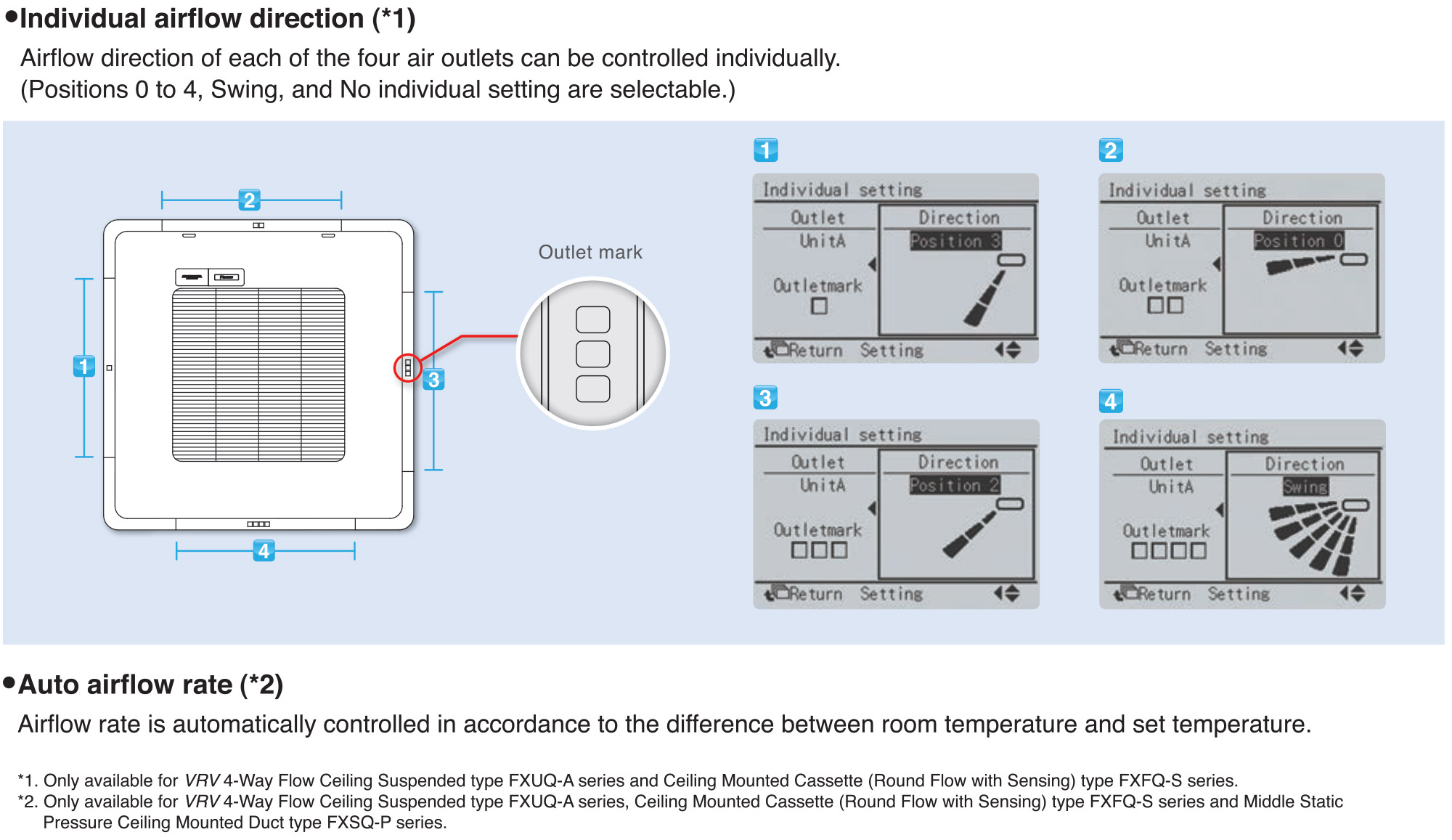

Navigation Remote Controller (Wired remote controller) (Option)

Simple operation

Energy Saving

Convenience

Comfort

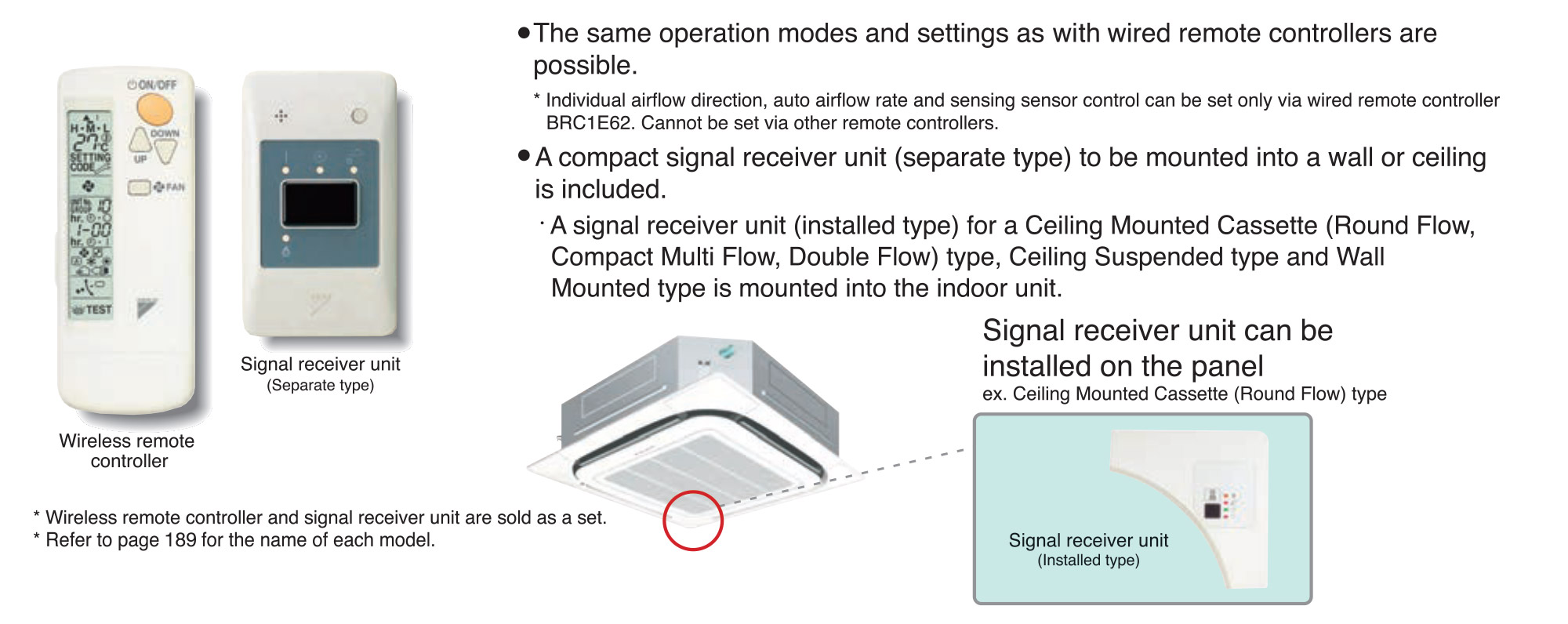

Wireless remote controller (Option)

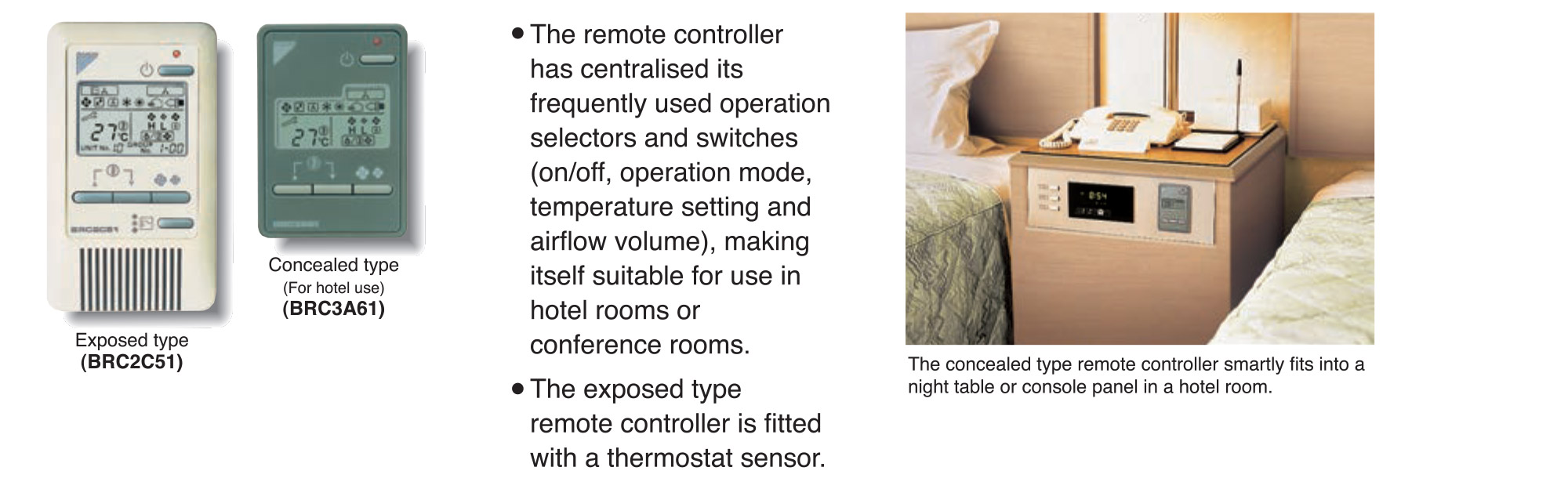

Simplified remote controller (Option)

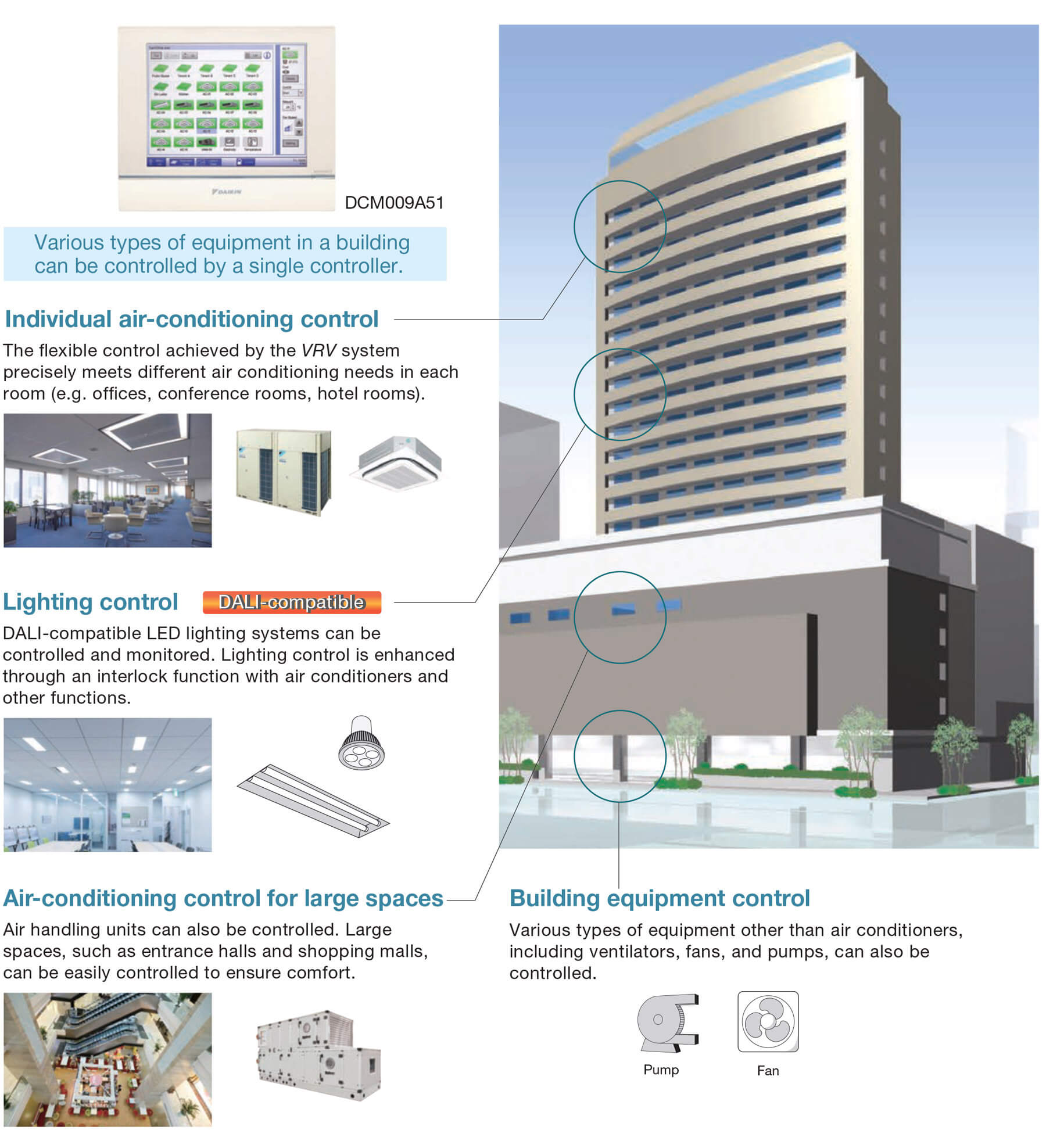

Integrated Building Monitoring System

Advanced Control Systems for VRV Indoor Units

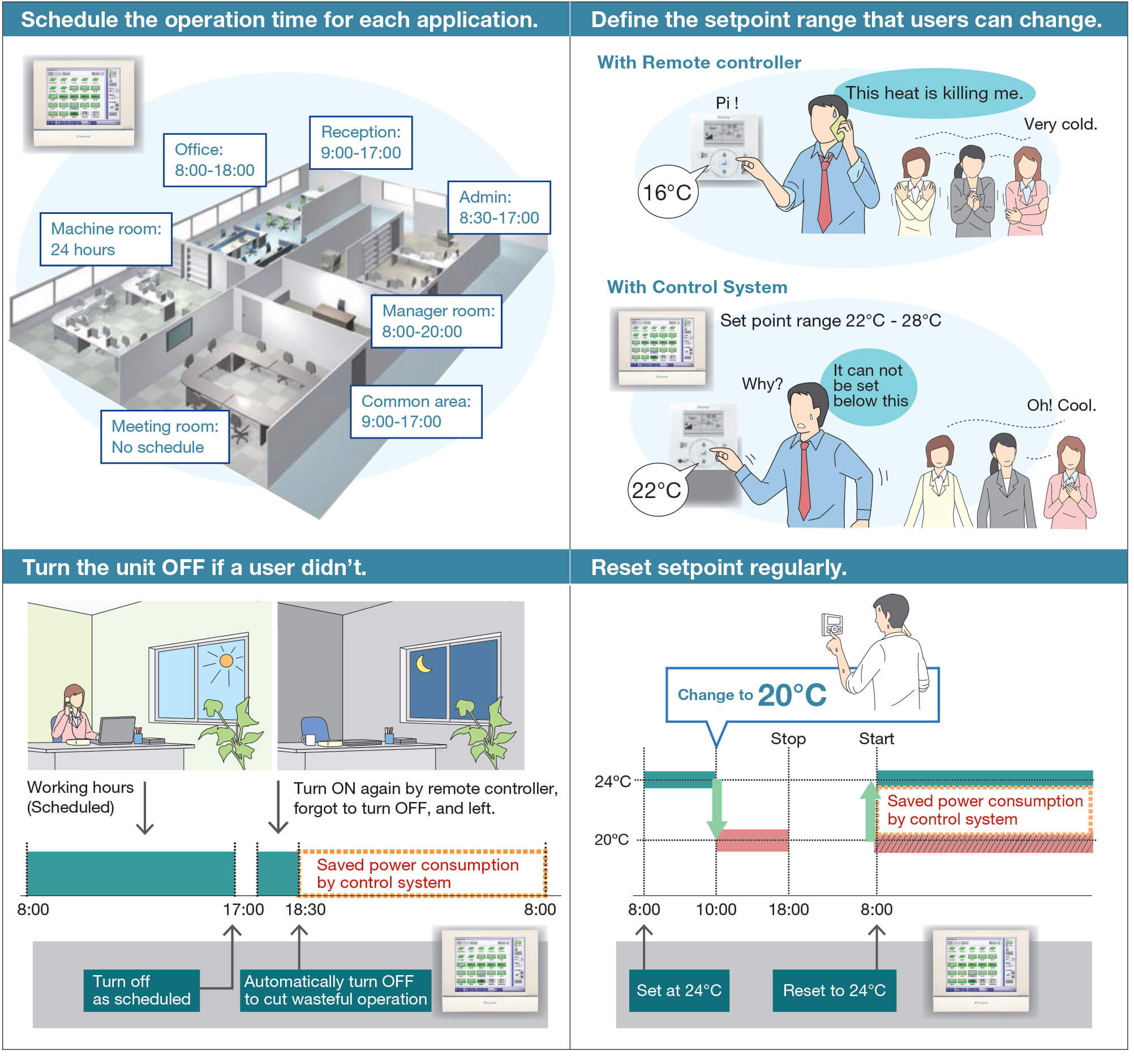

One touch selection enables flexible control of equipment in a building.

For Energy Saving & Comfort

intelligent Touch Manager maximises the advantages of VRV features

intelligent Touch Manager is an advanced multi-zone controller that provides the most cost-effective way to control and monitor the Daikin VRV system.

The 10.4" LCD touch screen is easy to use with three different screen views to include the floor plan layout view, icon view and list view and menus for system configurations.

It is also easy to use with standardized remote Web Access from your PC.

It can manage a total of 650 management points consisting of up to 512 Daikin indoor unit groups (up to 1024 indoor units) along with building equipment control / monitoring with Digital Inputs / Output (Di/Dio), Analog Inputs / Output (Ai/Ao) and Pulse input (Pi) optional devices.

Specifications

Energy Efficient