Anti-Corrosion heavy and marine Treatment

Anti-Corrosion Heavy & Marine Treatment for Your Outdoor Units

Buildings, data centres, and resorts near the coast or in industrial zones face ongoing threats from salt-laden air, high humidity, mild chemicals, and airborne pollutants. These factors accelerate corrosion, which can lead to equipment failure and costly repairs.

Daikin’s Anti-Corrosion Treatments are specially formulated to shield your outdoor air-conditioning units from harsh environmental conditions. Whether it's a marine, coastal, or heavy industrial setting, our solution ensures long-lasting performance and protects your investment.

Corrosion is the deterioration of surfaces caused by environmental reactions—such as salt, chemicals, and humidity. Our treatments work by:

- Coating exposed components of your AC system

- Preventing rapid corrosion formation

- Extending equipment lifespan

- Maintaining energy-efficient performance

An additional protection option includes PCB coating, ideal for locations with severe air quality degradation.

Examples of Corrosion:

.jpg)

.jpg)

With our outdoor solutions, your equipment remains protected and operational even in the most challenging environments.

Find out more: Anti-Corrosion Microbial Catalogue

Why Coastal and Marine Environments Are Tough on Air Conditioners?

Coastal air carries high salt content and humidity, which accelerates rust, coil degradation, microbial growth, and corrosion of key components. Left untreated, this leads to:

- Frequent repairs due to copper/fins oxidisation

- Higher energy bills

- Reduced cooling efficiency

- Shortened equipment lifespan

- Risk of white spots forming on coil fins within 6 months

| Anti-Corrosion Heavy Treatment | Anti-Corrosion Marine Treatment | |

|---|---|---|

| Corrosion Prevention | ||

| Anti-Bacteria & Anti-Fungal & Anti-Mould (Better Indoor Air Quality) | - | - |

| Extended Lifespan | ||

| Lower Maintenance Costs | ||

| Maintains Efficiency | ||

| *Applications* | Beachfront Resorts | Ferry Terminals / Seafront Resorts |

| Industrial Factories | Cruise / Onboard Ships |

ASTM Certified Test

| Standard | Description | Conditions | Result | Remark |

|---|---|---|---|---|

| G21 | Anti-Fungi Test | 28 days | Pass | |

| G22 | Anti-Bacteria Test | 28 days | Pass | |

| G85-A5 | Acidified Salt Spray Test | 1000/3000h | Good | |

| G87 | Moist SO2 Test | 50 Cycles | Pass | |

| B117 | Salt Spray Test | 10000h | Pass | |

| D4798 | UV Exposure Test |

1000 hours Weathering, Xenon Arc Test Method |

9.8 |

Rating scale 0 – 10 (10 = highest) |

| D5894 | UV Corrosion Exposure Test |

1000 hours Cyclic Corrosion/UV Exposure of Painted Metal |

1.0 |

Rating scale 0 – 10 (10 = highest) |

| D2794 | Impact Resistance Test | Effect of rapid deformation | Good |

|

| D522 | Flexibility Test | Method B: flexibility and adhesion | Excellent | No Cracking Detected; 100% Adhesion |

Note: *Contact us now for more information on our Antimicrobial Treatment

Applicable Environments

Outdoor Environment - Corrosion Resistance (ODU) + Fresh Air Unit

Applications

Anti-Corrosion Heavy Treatment

-

Condominiums -

Shopping Malls -

HDBs -

Landed Properties -

Hotels -

Office Towers

Anti-Corrosion Marine Treatment

-

Shipyards -

Vessels -

Mild Chemical Industries -

Offshores -

Ports -

Coastal Areas

Applicable Products

The treatment is compatible with Daikin’s full HVAC lineup, including a wide range of indoor and outdoor models such as Split Units, SkyAir Systems, VRV Systems, Packaged Units, Air-Handling Units, Chilled Water Fan Coil Units, and Air-Cooled Chillers.

Outdoor Units

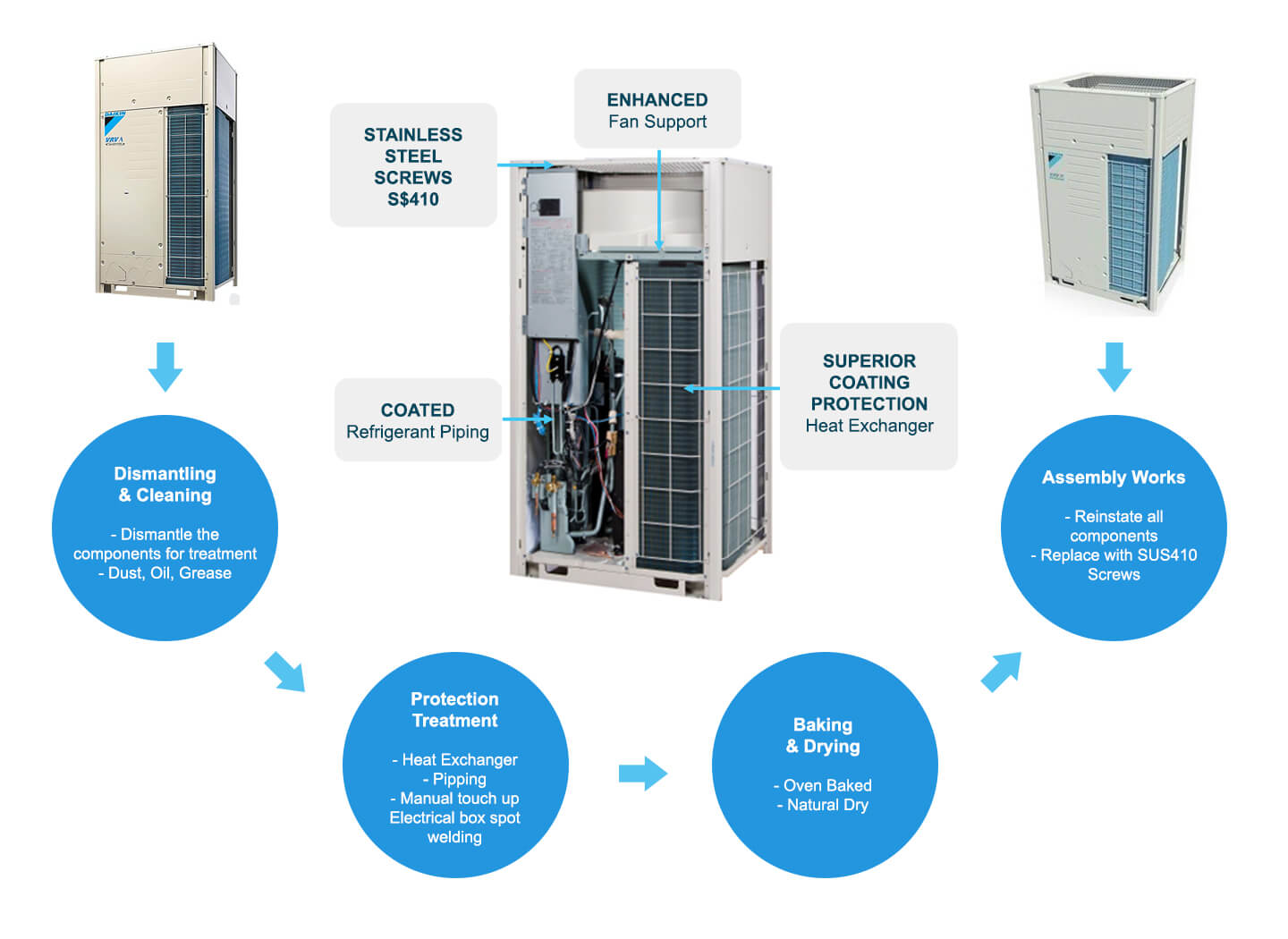

Anticorrosion Process

Manuals

Care and maintenance instruction

Do’s

- Wash the coil with fresh water regularly - Do wash the coil regularly with fresh water to ensure the coil is at optimum condition. (Bi-Monthly)

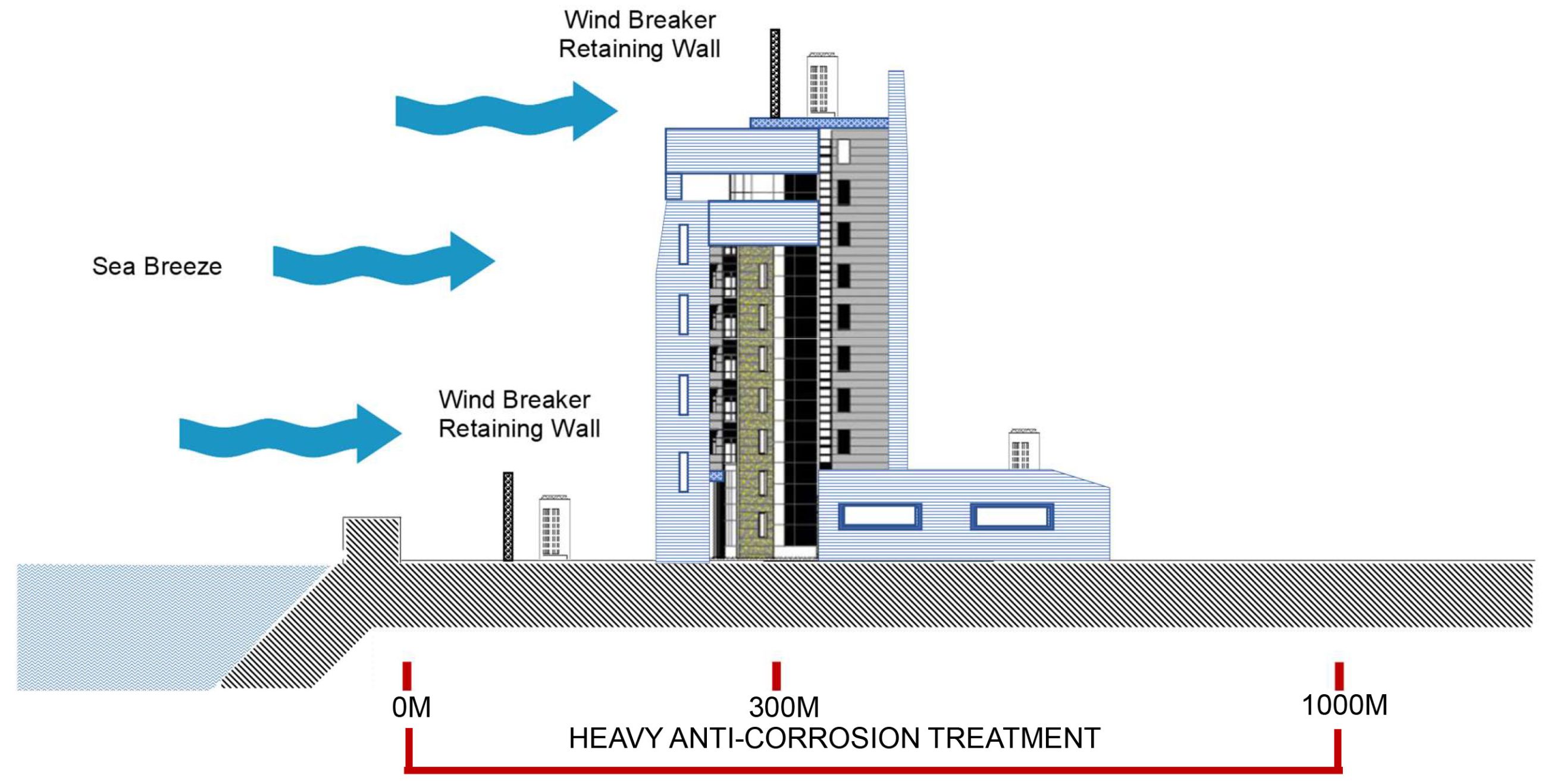

- Prevent direct contact with sea water and coastal sand - Do ensure equipment with adequate encloses protection.

- Protect the equipment from direct sea breeze - Do ensure equipment is protected with wind breaker.

- Handle the equipment with care during handling work - Do ensure no scratches on the protection coating during handling and maintenance works.

- Touch up work with anti-corrosion paints regularly - Do touch up with anti-corrosion paints on any rusty parts regularly during maintenance work.

- Select correct and suitable location - Do ensure location is unblock/dry and away from sandy location.

Don’ts

- Wash the coil with acid or unknown chemical - Do not wash the coil with any acid or unknown chemical.

- Use high pressure (spray jet) on the coil during cleaning works - Do not use high pressure spray jet to avoid flatten or fins damages.

- Allow direct contact with sea water and sandy sands - Do not allow direct contact with sea water (avoid formation of salt) and sandy sand (avoid from scratching the coating)

- Leave any unwanted materials on the bottom frame - Do not leave any foreign particle on the bottom frame to ensure no hard materials and always maintain cleanliness.

- Mishandle or modify the equipment - Unauthorize modification the unit will void the warranty of the equipment.

- Replace new coated condenser coil on the corroded bottom frame - Do not replace new coated condenser coil on corroded bottom frame to avoid further deterioration to ensure all parts is corrosion free.

Installation and Precaution

- It is important not to install the equipment directly exposed to sea water.

- Avoid sandy location i.e. near the shore.

- Select a well-drained location.

- Extra care is required during hoisting and handling the equipment to prevent scratches on the protection coating.

- No sharp material to be use during handling.

- Clear all unwanted debris/drilling particles on the bottom frame.

- For prolong storage at site before operation, do protect the equipment with existing packaging box prior to handing over.

- In situation where the unit is installed close to coastal area and expose to strong sea breeze, it is important to install a windbreaker/retaining wall to prolong the life span of the equipment protection coating.

Project References

Local Projects

Global Projects

- Indonesia

-

- St Regis – Bali

- MD Villa – Jakarta

- RSCM Hospital

- Green Hill

- Maldives

-

- Saman Villa

- Shangrila Roxy

- Gaakoshibee

- Male Airport

- Ran Finiho

- Como Resort

- Flux Resort

- Six Sense

- Spa Water Villa

- Sheraton

- Shingha

- Jumeirah

- Capella

- NDU Island & Spa M

- Valigandu

- Villa Isabella

- Seychelles

-

- Pension Fund NE Point

- Seychelles Apartment

- Noth OLME Hotel

- Four Season Resort

- Ahmad Manikus Residence

- Seychelles Port

- Praslin Seychelles

- Sri Lanka

-

- 92 Dharmapal

- Maga Omegaline

- Holiday Home

- The Emperor

- Fairway

- Maga Head Office

- Monarch Service Apartment

Contact Us

Contact us today to explore how Daikin can enhance your air-conditioning equipment!

Call: 6311 8686

Email: service@daikin.com.sg

OR